Introduction

In modern automotive and industrial manufacturing, precision spring grinding is essential for achieving the required dimensional accuracy, parallelism, and surface finish of coil springs. F-type spring grinding machines, typically vertical automatic setups, play a critical role in grinding both ends of the spring simultaneously. This ensures perfect flatness, consistent free length, and smooth surfaces—all key factors in components such as suspension springs, clutch springs, and valve springs.

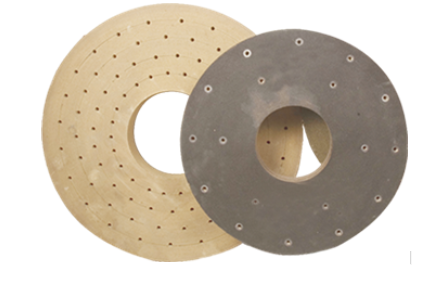

As manufacturers push for higher productivity, longer wheel life, and improved part quality, the choice of grinding wheel bond system becomes a decisive factor. To address these evolving needs, CUMI has engineered an advanced solution:

Enhancing F-Type Spring Grinding with CUMI’s BCSG Bond Technology

In spring-end grinding, achieving a uniform finish while maintaining cooler cutting conditions is crucial. F-type machines demand grinding wheels that can withstand heavy loads, deliver consistent results, and maintain their shape throughout long production cycles.

CUMI’s BCSG (Bonded Cool Spring Grinding) bond system is specially designed for both automatic and non-automatic spring grinders. It delivers enhanced grinding efficiency, reduced heat generation, longer wheel life, and superior surface quality—making it a next-generation abrasive solution for spring manufacturing.

What is the BCSG Bond System?

The BCSG bond is an advanced resin-based formulation developed specifically for heavy-duty spring grinding. It is engineered to maintain a cooler grinding zone, reduce thermal damage at the spring ends, and ensure consistent performance throughout the wheel’s life.

Key Features of the BCSG Bond

Optimized Bond Strength

Prevents grain pull-out and improves wheel durability, resulting in extended wheel life.Advanced Resin Technology

Lowers heat generation during grinding, ensures cool cutting, and minimizes burn marks on springs.Batch-to-Batch Consistency

Maintains form, shape retention, and stable grinding rates across long production runs.Lower Power Consumption

Reduces spindle load, enabling smoother operation and energy efficiency.

Performance Insights: Proven Results in Real-World Applications

CUMI evaluated the BCSG bond on a production F-type spring grinding setup. The results highlighted significant improvements over standard reference wheels.

Parameter | Reference Wheel | BCSG Bond Wheel |

Surface Finish | < 0.80 μm | < 0.60 μm |

Dressing Frequency (components per dress) | 1600 | 3200 |

Overall Wheel Life | 55,000 | 85,000 |

Cycle Time | 26 min | 17 min |

Key Findings

2X improvement in dressing frequency

Smoother surface finish, indicating cooler and more stable grinding

~35% reduction in cycle time

Higher wheel life, lowering overall cost per component

These improvements directly translate into increased productivity, reduced downtime, and better operational efficiency.

Key Advantages of BCSG Bond Wheels

✔ Cool Cutting Action

Effective heat dissipation prevents burn marks, improves surface integrity, and ensures superior finish quality.

✔ Extended Wheel Life

Higher bond strength and thermal stability provide longer dressing intervals and more consistent grinding performance.

✔ Consistent Dimensional Accuracy

BCSG wheels maintain shape and form throughout their life, ensuring stable parallelism and precision in spring geometry.

✔ Higher Productivity

Faster stock removal, reduced cycle times, and improved grinding stability enable manufacturers to increase output without compromising quality.

Application Areas

CUMI’s BCSG bond wheels are ideal for spring grinding requirements across multiple sectors, including:

Coil springs

Leaf springs

Shock absorber components

Automotive chassis parts

Engine and powertrain components

Clutch and transmission systems

Conclusion

The BCSG bond system marks a major advancement in abrasive technology for spring grinding applications. By combining high cutting efficiency, superior thermal control, and enhanced durability, CUMI delivers a solution that significantly boosts productivity and reduces operational costs.

For manufacturers using F-type spring grinding machines, CUMI’s BCSG bond provides the ideal balance of performance, wheel life, and component quality. As industries continue to demand improved throughput and reliability, the BCSG bond system stands out as a next-generation abrasive technology designed to deliver measurable results.

Frequently Asked Questions

1) What does “BCSG” stand for in CUMI’s BCSG bond technology?

BCSG stands for Bonded Cool Spring Grinding. It’s a specially engineered resin bond system designed to provide cooler cutting, longer wheel life, and superior surface finish during spring grinding operations.

2) How does the BCSG bond improve F-type spring grinding performance?

The BCSG bond ensures better thermal control, reduces burn marks on spring ends, and allows for faster material removal. It helps maintain consistent wheel shape and extends dressing intervals, resulting in reduced cycle times and higher productivity.

3) What types of springs and components can benefit from BCSG bond grinding wheels?

BCSG bond wheels are ideal for grinding coil springs, clutch springs, valve springs, leaf springs, and other automotive or industrial components requiring precise parallelism and surface finish.

4) How does the BCSG bond contribute to lower operational costs?

With improved wheel life, extended dressing intervals, and reduced power consumption, the BCSG bond minimizes wheel changes, machine downtime, and energy usage—ultimately lowering the cost per component.

5) Can BCSG bond wheels be used on both automatic and manual spring grinding machines?

Yes, the BCSG bond is designed for versatility. It performs effectively on both automatic F-type machines and non-automatic setups, ensuring consistent grinding quality across varied production lines.