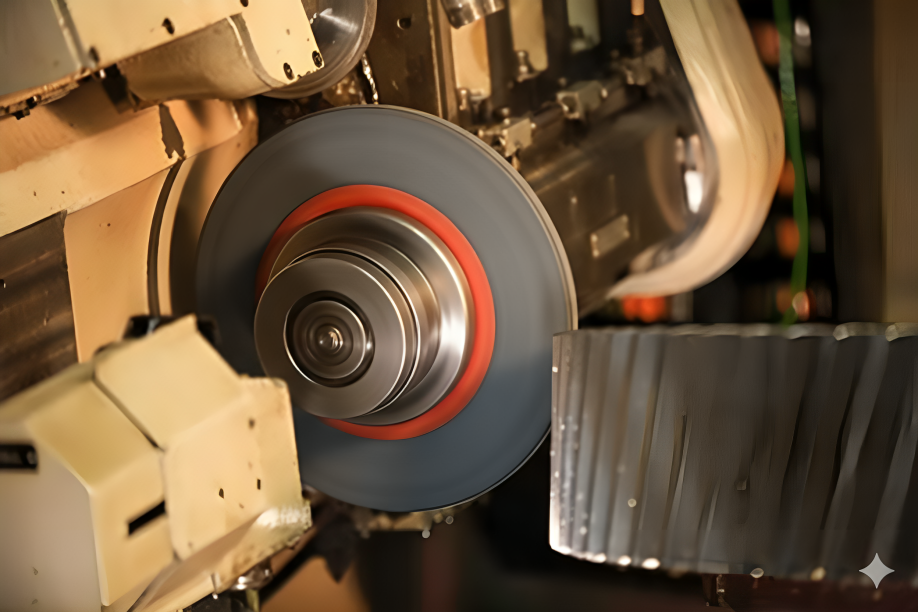

In the world of modern engineering, gears are the unsung heroes of motion and power transmission. From automotive to aerospace, from railways to wind energy, industries today demand higher power density, quieter operation, and greater efficiency. But achieving these performance benchmarks requires gears that meet extremely tight tolerances, have flawless profile accuracy, and have an exceptional surface finish.

This is where single-rib gear grinding emerges as the benchmark finishing process for high-precision gears.

Why Single-Rib Gear Grinding Matters

Unlike conventional gear finishing methods, single-rib gear grinding ensures consistency in profile, lead accuracy, and surface finish. It directly impacts gear reliability, noise levels, and long-term performance—making it the preferred choice for manufacturers striving to deliver excellence.

For product managers and industry leaders, this translates to:

- Improved gear reliability → fewer failures in critical systems.

- Optimized efficiency → reduced power losses, supporting sustainability.

- Enhanced customer trust → gears that perform quietly and last longer.

CUMI’s Next-Generation Gear Grinding Solutions

At Carborundum Universal Limited (CUMI), we combine decades of abrasive expertise with cutting-edge innovation to offer high-performance gear grinding wheels that redefine industry standards.

Our wheels are manufactured using advanced bonds and high-performance abrasive grains to achieve both productivity and precision—two goals that are often considered trade-offs in conventional grinding.

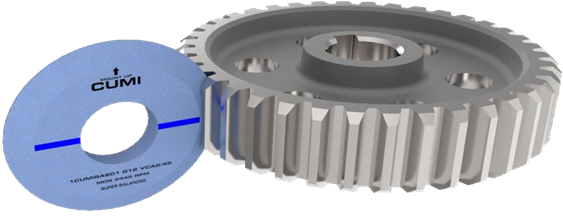

Key innovations include:

- High volumetric stock removal (Q’w): Faster grinding cycles without accuracy loss.

- Advanced bond technology: Superior form retention and surface finish.

- Unique grain morphology: Reduced friction and wear, ensuring longer gear and wheel life.

Flexibility Across Applications

CUMI offers gear grinding wheels with:

- Grit sizes: 46–120

- Outer diameters (OD): up to 508 mm

- Operating speeds: up to 60 mps

This versatility makes our solutions ideal for:

- Automotive transmissions—quieter, fuel-efficient vehicles.

- Railway gears—reliability in heavy-duty operations.

- Wind energy gearboxes—durability in demanding environments.

- General engineering—cost-effective precision across industries.

The CUMI Advantage: Benefits for Manufacturers

High stock removal → faster throughput, higher productivity.

Consistent accuracy → precise geometry for reliable performance.

Lead and profile retention → smoother power transmission.

Superior surface quality → quieter operation and extended gear life.

Driving the Future of Gears with Precision

Gear manufacturers face pressure to deliver higher quality at a lower cost in an increasingly competitive market. CUMI’s single-rib gear grinding solutions are more than just tools—they are enablers of precision, performance, and trust.

For industry leaders, the choice is clear: invest in next-generation gear grinding solutions that shape the future of mobility and engineering.

Frequently Asked Questions

1) Where can I order CUMI single rib gear grinding wheels?

The Single Rib Gear grinding wheels are available through online enquiry on the website or email enquiry.

2) Why do precision gear manufacturers select CUMI single-rib solutions?

For unmatched consistency in profile accuracy, superior lead accuracy, and a highly reliable surface finish across every batch.

3) What makes CUMI single rib gear grinding wheels effective?

Advanced bonds and high-performance abrasive grains ensure high stock removal, superior form retention, and minimal friction, delivering precise geometry and long-lasting wheel life.

4) Which industries benefit most from CUMI single rib gear grinding?

Automotive, railway, wind energy, and general engineering sectors requiring quiet, efficient, and high-precision gear performance.

5) What fluid is recommended for best results with these wheels?

Use high-performance grinding oils/coolants to optimize cooling and surface quality.