Creep-feed grinding wheels play a crucial role in the aerospace industry, where precision is not just a requirement—it’s a necessity. Components like turbine blades, vanes, and engine parts are manufactured from advanced alloys that demand extremely tight tolerances, superior surface finishes, and exceptional form accuracy. At the same time, these critical parts often require the removal of high grinding allowances, making finishing operations both complex and essential.

The challenge for aerospace manufacturers lies in achieving high material removal rates while maintaining geometry and surface integrity. Any change in form or quality can affect the part and, more importantly, the aircraft’s performance and safety. This aspect is where CUMI’s creep-feed grinding wheels make a decisive difference.

Why Aerospace Manufacturing Needs Creep-Feed Grinding

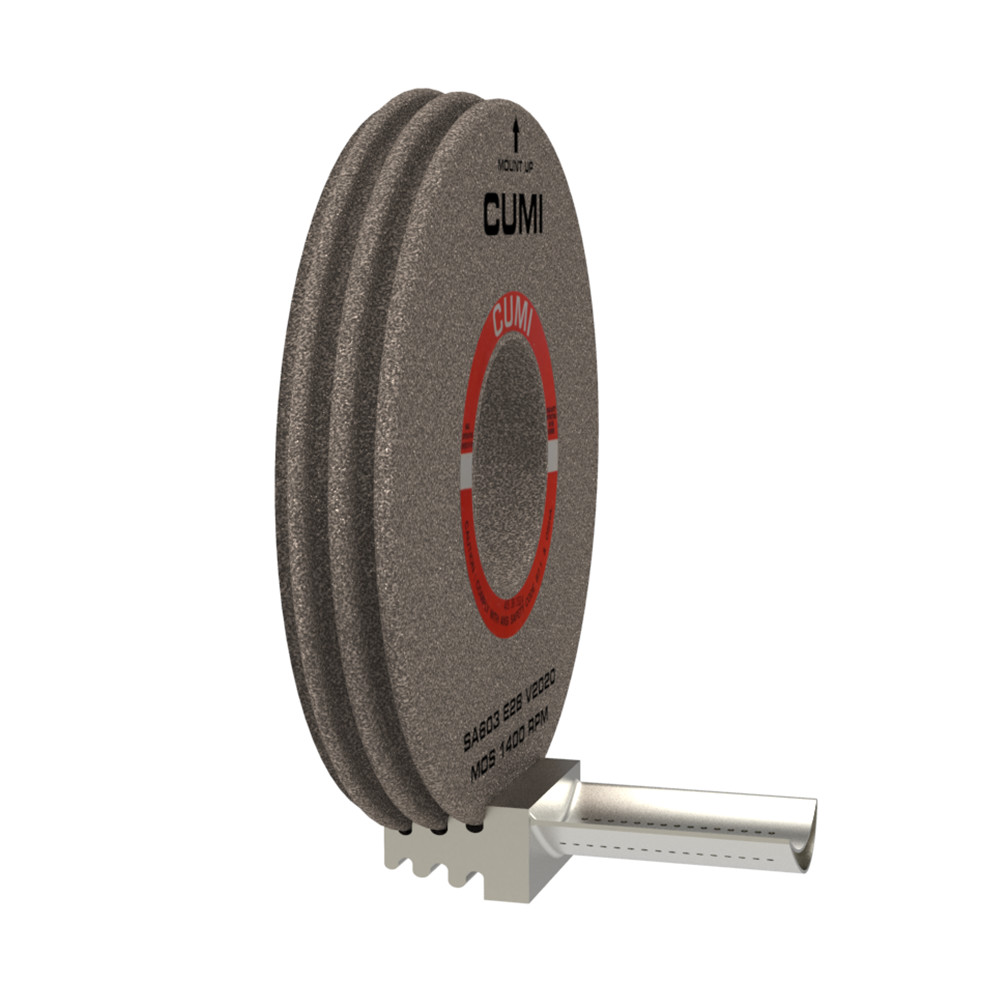

Creep-feed grinding is ideal for applications that demand high stock removal without sacrificing dimensional accuracy or surface quality. Aerospace components are often made from heat-resistant superalloys (HRSA), which are difficult to machine using conventional methods. High-feed grinding can lead to thermal damage, burns, or uneven surfaces—issues that are unacceptable in aerospace manufacturing.

CUMI’s advanced grinding solutions are engineered to tackle these challenges, delivering precision, efficiency, and reliability in every operation.

The Aerospace Advantage with CUMI

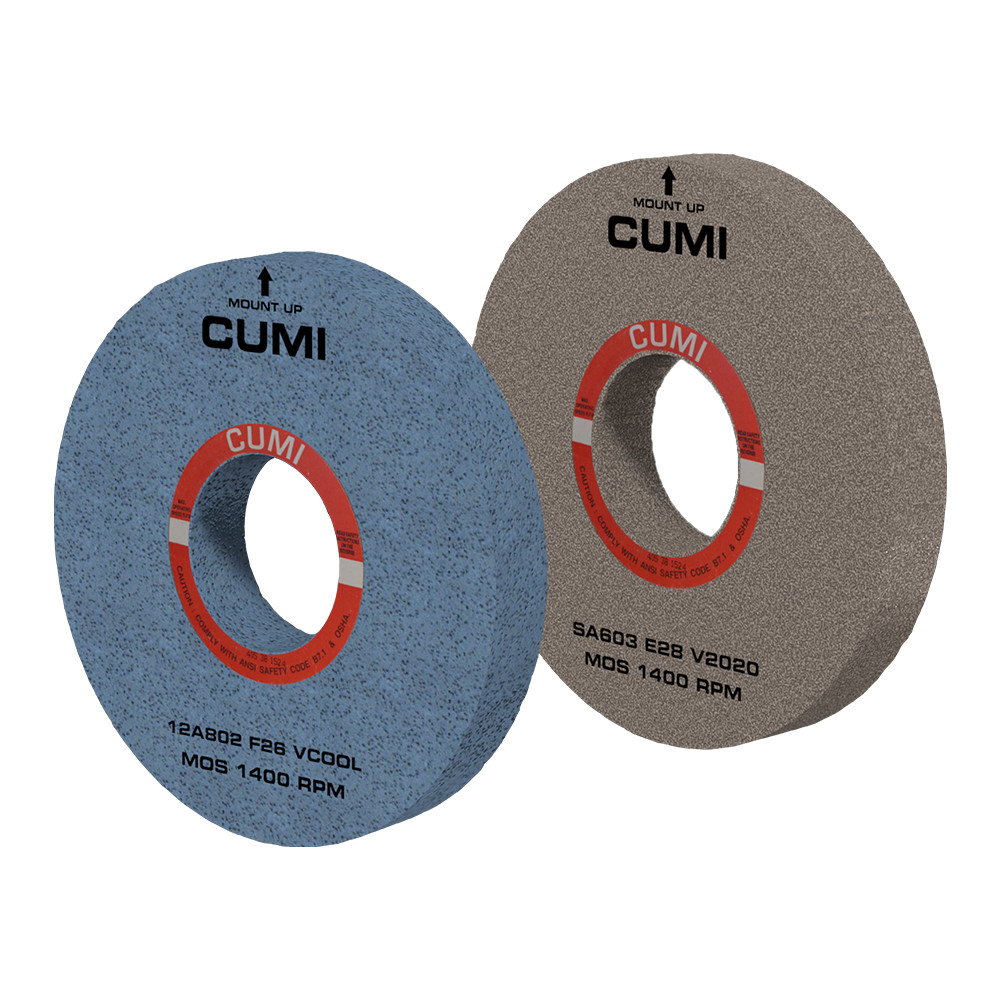

CUMI’s creep-feed grinding wheels are specifically designed for high material removal operations, ensuring that aerospace manufacturers achieve both productivity and uncompromising quality. Whether using continuous dressing or intermediate dressing, CUMI wheels maintain consistent form and finish while operating at high feed rates. This reduces dressing frequency, improves cycle efficiency, and guarantees burn-free surfaces—a critical factor when working with aerospace alloys.

Key Features of CUMI Creep-Feed Grinding Wheels in Aerospace

- Free-cutting abrasives: Enable smooth grinding of heat-resistant superalloys without compromising surface integrity.

- Fusible, glassy bond: Provides superior form holding even under heavy loads.

- Uniform open pores: Ensure excellent coolant flow and thermal control during the grinding process.

- Advanced molding techniques: Guarantee product consistency and reliable performance across all operations.

Advantages for Aerospace Manufacturers

- High feed rates: Achieve shorter cycle times and faster part throughput.

- Controlled wear: Longer wheel life reduces operational expenses.

- Burn-free surfaces: Preserve the material properties of turbine blades and engine components.

- Gentle on dressing rolls: Minimize tooling expenses and downtime.

- Reliable form holding: Maintain flawless component geometry for critical aerospace parts.

Driving Aerospace Precision

In an industry where the margin for error is virtually zero, CUMI’s creep-feed grinding wheels strike the perfect balance between productivity, accuracy, and consistency. By allowing quicker production times without sacrificing surface quality or size accuracy, CUMI helps aerospace manufacturers keep up with the need for greater efficiency while making parts that are safe for flight.

With CUMI, aerospace manufacturers achieve the precision that powers performance.

Frequently Asked Questions

1) Where can I purchase CUMI’s aerospace-grade creep-feed grinding wheels?

The Creep Feed grinding wheels are available through online enquiry on the website or email enquiry.

2) What makes CUMI creep-feed wheels the right choice for aerospace components?

They are engineered for high stock removal, reduced thermal damage, and exact surface finishes required in aerospace manufacturing.

3) Why is creep-feed grinding suitable for aerospace alloys?

It provides high material removal rates while maintaining geometry and surface integrity, essential for complex, heat-sensitive aerospace parts.

4) What advantages do CUMI wheels offer in reducing cycle time?

Superior bond and abrasive technology extend intervals between dressings, streamlining production cycles.

5) What advantages do aerospace manufacturers gain from using these abrasive solutions?

CUMI Abrasives provide aerospace manufacturers with high precision, longer tool life, reduced clogging, improved surface finish, lower heat generation, and increased productivity, helping reduce overall manufacturing time, wear, and operational costs.