Grit selection is one of the most critical aspects of sanding and grinding, yet it is often misunderstood and incorrectly applied. Choosing the wrong grit can increase cycle time, damage surfaces, or reduce abrasive life. This guide explains what grit sizes mean, how they affect surface finish and productivity, and how to select the right grit for different applications across coated abrasives and grinding wheels.

What Is Grit Size?

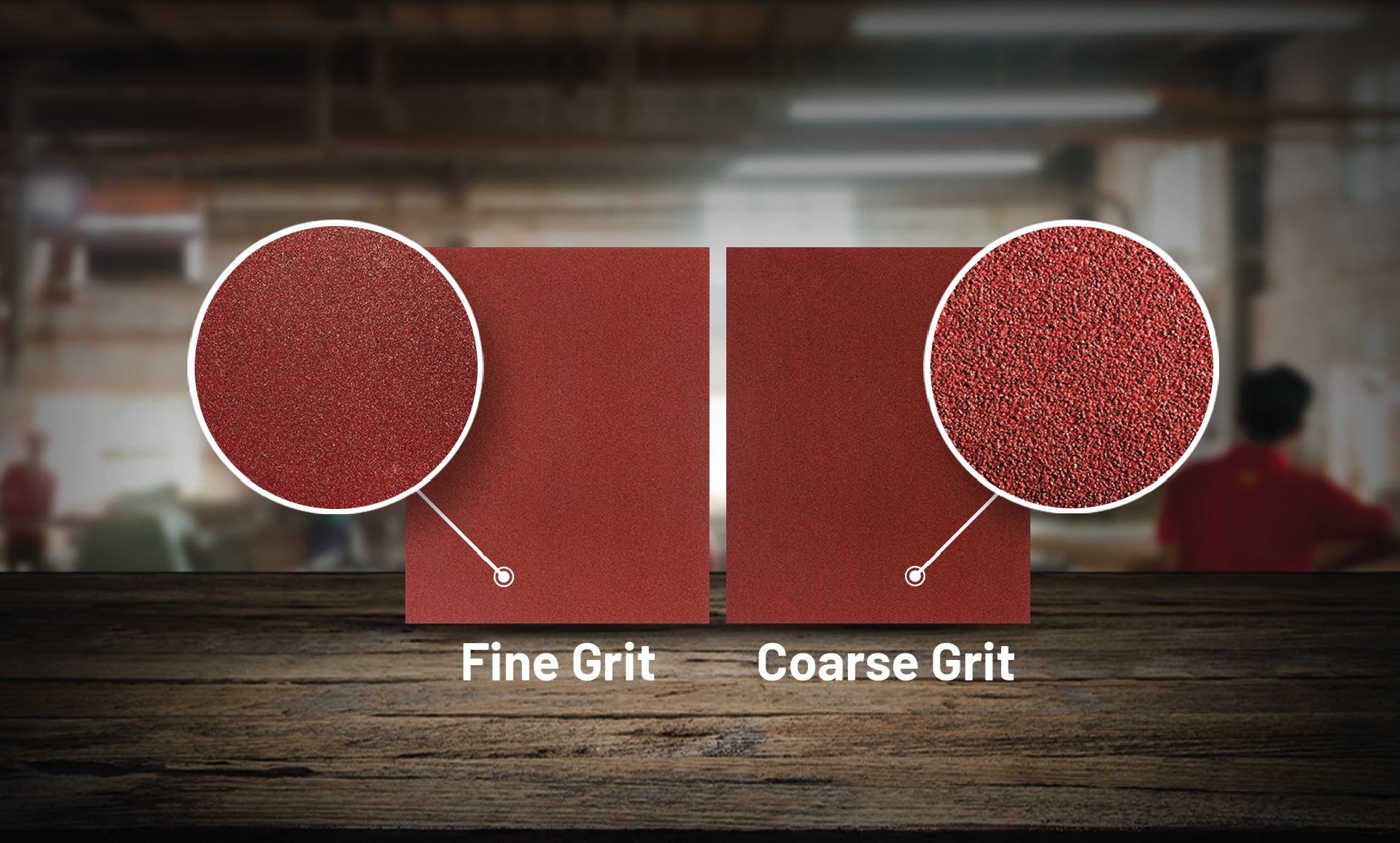

Grit size refers to the number of abrasive particles per square inch on a sanding sheet, belt, disc, or grinding wheel.

- Lower grit numbers (coarse) have larger abrasive grains

- Higher grit numbers (fine) have smaller abrasive grains

Understanding this scale helps operators control material removal rate, surface quality, and process efficiency.

How Grit Size Affects Surface Finish

- Coarse Grits (24–80)

Used for heavy stock removal, leveling rough surfaces, weld removal, and paint stripping. These grits leave deeper scratch patterns but remove material quickly. - Medium Grits (100–150)

Ideal for surface smoothing, shape correction, and preparation before finishing. Commonly used in woodworking, metal finishing, and wall sanding. - Fine Grits (180–600+)

Designed for final finishing, blending, and surface refinement. Fine grits reduce visible scratches and prepare surfaces for polishing, coating, or painting.

Selecting the correct progression of grits ensures a clean finish without rework.

How Grit Selection Impacts Finish & Productivity

Correct grit selection directly affects productivity in sanding and grinding operations:

- Using too fine a grit too early does not help material removal and can lead to glazing, heat buildup, and inefficient grinding.

- Using too coarse a grit for finishing causes surface scratches, which increases rework and polishing time.

- Correct grit sequencing reduces abrasive consumption and cycle time

For example, starting with a coarse grit for stock removal and gradually moving to finer grits allows faster completion with consistent surface quality.

Grit Selection by Product Category

- Sanding Sheets & Rolls

Used in wood sanding, wall preparation, auto aftercare, and furniture finishing. Medium to fine grits are commonly used for smooth, even finishes. - Sanding Belts & Wide Belts

Used in metal grinding, panel sanding, and calibration, where coarse to medium grits improve productivity. - Grinding Wheels

Coarse grits are used for snagging and heavy grinding, while finer grits are used for precision and surface grinding applications.

Matching grit size to the product category ensures optimal performance and safety.

Common Grit Selection Mistakes to Avoid

- Skipping grit steps, causing visible scratch marks

- Applying excessive pressure instead of changing grit

- Using worn abrasives beyond their effective life

Correct grit choice improves both finish quality and abrasive lifespan.

FAQs – Grit Size & Abrasive Selection

1. What grit should I start with for rough sanding?

Start with coarse grits like 36 or 60 for heavy material removal.

2. Which grit is best for smooth finishing?

Use 180 grit and above for fine finishing and surface refinement.

3. Can one grit be used for all sanding steps?

No. Progressive grit changes are required for efficient sanding and a better finish.

4. Does grit size affect abrasive life?

Yes. Using the correct grit reduces wear and improves abrasive durability.

5. Is grit selection important for productivity?

Absolutely. Correct grit choice reduces cycle time and minimizes rework.