Introduction

In the bearing industry, where micron-level precision defines performance, grinding wheels play a critical role in ensuring surface finish, geometry, and dimensional accuracy. Conventional bond types often face limitations such as high heat generation, glazing, and frequent dressing—leading to increased downtime and cost.

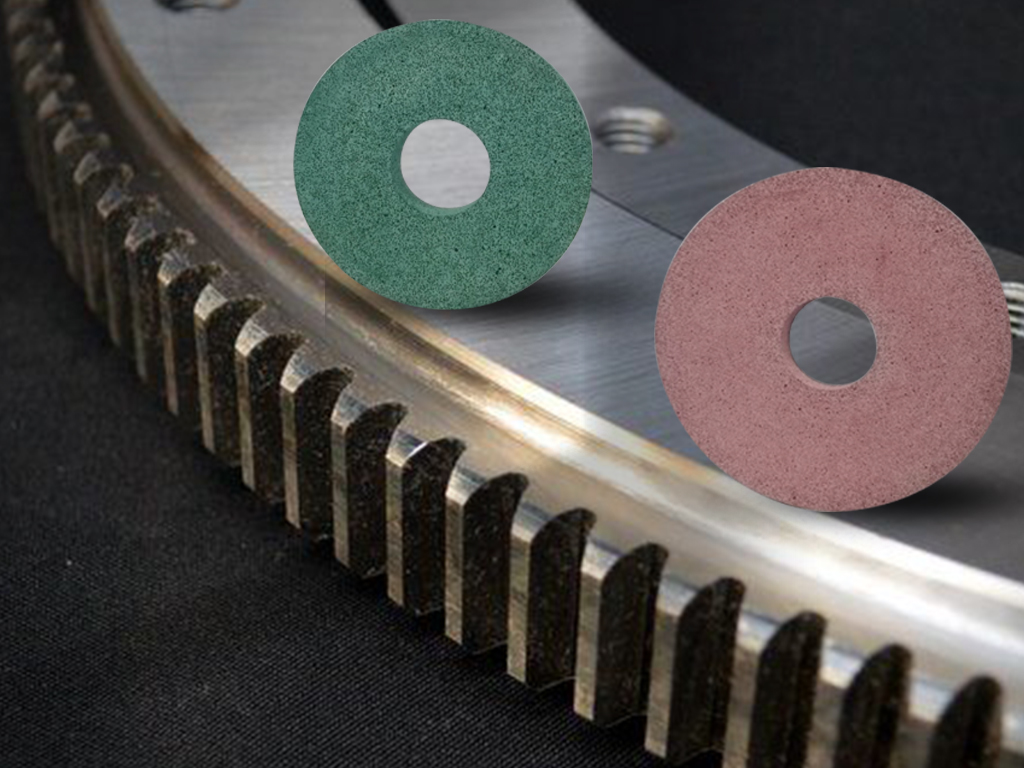

CUMI’s Epoxy Bonded Grinding Wheels are engineered to overcome these challenges, offering superior grinding precision, cooler operation, and extended wheel life across applications like Taper Roller Bearings (TRB), Deep Groove Ball Bearings (DGBB), and Roller Grinding.

Why Epoxy Bonding Technology Matters

Epoxy bond technology represents a new generation in precision grinding. By combining high-strength epoxy resins with controlled abrasive dispersion, these wheels deliver excellent form retention and consistent grinding performance—even under demanding conditions.

Key Advantages of CUMI Epoxy Bonded Grinding Wheels

Performance Benefits

- Superior Surface Finish & Geometry Accuracy – Achieves tight dimensional tolerances with fine surface quality.

- Cooler Grinding – Reduces thermal damage, burns, and metallurgical cracks on the workpiece.

- Smooth and Quiet Operation—Minimizes machine vibration and enhances operator comfort.

- Excellent Form Retention—Maintains wheel shape for longer, ensuring consistent part quality.

- Chemical and Coolant Resistance – Performs reliably across various coolant types and machining environments.

- Reduced Dressing Frequency – Extends production runs between dressings, improving machine uptime.

Quality Advantages

- Superior and Consistent Surface Finish

- Dimensional Stability and Repeatability

- Reduced Wheel Loading and Glazing

- Minimized Thermal and Metallurgical Damage

These benefits ensure defect-free bearings and reduced rework rates, crucial in high-precision environments like automotive, aerospace, and industrial manufacturing.

Operational Benefits

- Stable grinding with minimal vibration

- Easier wheel mounting and balancing

- Lower machine noise

- Reduced power consumption—translating to energy savings

Together, these attributes make CUMI’s epoxy-bonded wheels ideal for high-volume bearing production lines.

Cost Efficiency and Productivity

CUMI’s epoxy-bonded wheels deliver measurable cost savings through longer life, reduced dressing, and minimal scrap.

- Longer Wheel Life

- 1.5–2× longer than traditional phenolic resin wheels

- 25–35% reduction in annual wheel replacement costs

- 1.5–2× longer than traditional phenolic resin wheels

- Reduced Dressing Frequency

- Dressing intervals extended by 30–50%

- 25–40% savings on diamond dressing tool costs

- Dressing intervals extended by 30–50%

- Reduced Scrap and Rework

- Up to 40% reduction in regrind and rejection rates due to cooler grinding and better form control

- Up to 40% reduction in regrind and rejection rates due to cooler grinding and better form control

These improvements help manufacturers achieve lower cost per part while maintaining consistent performance.

Applications

Epoxy-bonded grinding wheels are suited for a wide range of bearing and precision component applications:

Process | Typical Components | Applicable Bearings |

Double Disc Face Grinding | Inner & Outer Races, Rollers, Balls | TRB, DGBB, CRB, SRB |

Tool & Cutter Grinding | Carbide Tools | – |

Optical and Glass Grinding | Semiconductor & Ferrite Materials | – |

Mould and Die Grinding | Tool Room Components | – |

Materials Worked On:

Hard metals, ceramics, magnetic materials, ferrites, carbides, ferrous & non-ferrous metals, optical glass, and semiconductor materials.

Case Study Highlights

- Taper Roller Bearings (TRB) & Deep Groove Ball Bearings (DGBB):

Up to 30–40% higher wheel life is achieved with CUMI’s epoxy-bonded wheels. - Bearing Roller Grinding:

Delivered 25–35% improvement in wheel life compared to conventional bonds.

These real-world results showcase how CUMI’s innovation drives both performance and profitability.

Conclusion

CUMI’s Epoxy Bonded Grinding Wheels bring together advanced resin chemistry and precision engineering to redefine what’s possible in bearing grinding. With longer life, superior form stability, and cooler cutting action, they make high-precision grinding a stable, cost-efficient, and high-output process.

Whether you’re producing TRBs, DGBBs, or precision rollers—it’s time to experience the next generation of performance.

Experience Precision Like Never Before!

Upgrade to CUMI’s epoxy-bonded grinding wheels for exceptional surface finish, extended tool life, and consistent production quality.

Contact our team today for a customized grinding solution tailored to your application.

Frequently Asked Questions

1) What makes CUMI’s epoxy-bonded grinding wheels different from conventional resin or vitrified wheels?

CUMI’s epoxy-bonded wheels use advanced epoxy resin technology with controlled abrasive dispersion, which provides cooler cutting, superior form retention, and longer wheel life. Compared to traditional phenolic or vitrified bonds, they reduce heat generation, glazing, and dressing frequency, improving both quality and productivity.

2) In which bearing applications can epoxy-bonded grinding wheels be used?

They are ideal for Taper Roller Bearings (TRB), Deep Groove Ball Bearings (DGBB), Cylindrical Roller Bearings (CRB), and Spherical Roller Bearings (SRB). Typical processes include double disc face grinding of inner and outer races, rollers, and balls, as well as roller grinding and precision component finishing.

3) How Do Epoxy-Bonded Grinding Wheels Improve Cost Efficiency and Productivity?

Epoxy-bonded grinding wheels offer 1.5–2× longer life than conventional phenolic resin wheels and extend dressing intervals by 30–50%, improving overall productivity. This leads to 25–35% lower wheel replacement costs, 25–40% savings on diamond dressing tools, and up to a 40% reduction in scrap and rework—significantly lowering the total cost per part.

4) What kind of surface quality and dimensional accuracy can be expected?

CUMI’s epoxy-bonded wheels deliver superior surface finish, tight dimensional tolerances, and excellent geometry control. Their cooler grinding action minimizes burns, metallurgical damage, and wheel glazing, ensuring consistent, defect-free parts suitable for high-precision industries like automotive and aerospace.

5) How do epoxy-bonded grinding wheels enhance process stability in high-volume bearing production?

Epoxy-bonded grinding wheels provide consistent cutting behavior throughout their service life, ensuring stable forces, controlled temperatures, and uniform material removal. This process stability is critical in high-volume bearing production, as it helps maintain repeatable quality across batches, reduces unplanned stoppages, and supports tighter process control with minimal operator intervention.