Introduction

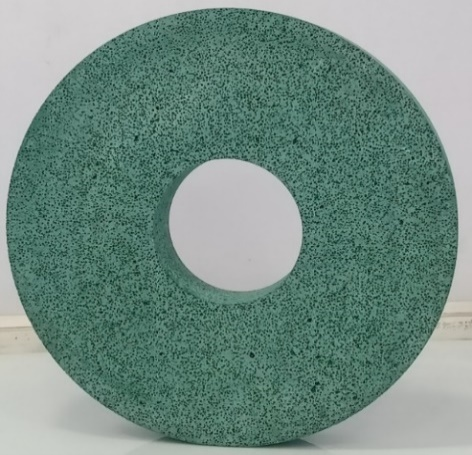

Epoxy-bond wheels are redefining performance standards in today’s competitive manufacturing landscape, where product managers and industry leaders face constant pressure to deliver precision, reduce costs, and maximize operational efficiency. While abrasive technology has seen incremental improvements over the decades, this innovation stands out as a true game-changer.

Unlike conventional phenolic-bonded wheels that struggle to balance toughness and hardness, epoxy-bond wheels provide an exceptional combination of strength, durability, and thermal resistance—delivering measurable business impact on the shop floor.

At CUMI, we are at the forefront of this transformation, engineering epoxy-bond wheels that consistently outperform traditional solutions in high-stakes industries like automotive, aerospace, medical, and precision tool manufacturing.

Strategic Advantages of Choosing Epoxy-Bond Wheels for Industry Leaders

For decision-makers, the true value of epoxy-bond technology lies not just in technical specifications but in the operational and financial advantages it unlocks:

- Extended Wheel Life = Reduced Procurement Costs

Longer wheel life translates directly into fewer replacements, lower inventory costs, and reduced procurement cycles. - Reduced Dressing Frequency = Higher Productivity

With up to 50% fewer dressing interruptions, production lines can maintain momentum and improve throughput. - Consistent Quality = Fewer Reworks

Stable bonding ensures superior surface finishes and dimensional accuracy, minimizing rejections and rework costs. - Operational Flexibility = Wider Applications

Epoxy bonds can be tailored to achieve specific hardness levels, making them a versatile solution across multiple grinding environments. - Thermal Stability = Process Reliability

Reduced heat generation preserves component integrity—critical in aerospace, medical, and high-precision applications.

Real-World Impact: Case Study in Bearing Inner Race Grinding

Consider railway bearing inner race grinding, a high-precision application where downtime and inconsistency carry heavy costs.

By switching to CUMI’s epoxy-bonded F-Type face grinding wheels, our clients achieved:

- 50% reduction in dressing frequency

- 25% lower cost per component

- 35% increase in wheel life

Key Results Delivered:

- 16,610 components ground per wheel

- 400–450 pieces before dressing (vs competitor’s 250)

- Surface finish: 0.3–0.4 Ra (well within ≤0.8 Ra spec)

- Flatness: 6–7 µm (below ≤10 µm tolerance)

- For senior managers, these results translate into:

Fewer production stoppages

Improved OEE (Overall Equipment Effectiveness)

Lower total cost of ownership

Why It Matters for Decision-Makers

In industries where precision and uptime are non-negotiable, the choice of abrasive technology directly influences profitability, customer satisfaction, and brand reputation.

Epoxy-bond wheels are not just a technical upgrade—they are a strategic investment:

- Lower maintenance costs

- Improved line efficiency

- Predictable, consistent output

CUMI’s expertise ensures that each wheel is engineered with proven chemistry and stable processes, giving leaders confidence in their production systems.

Conclusion

For industry leaders and product managers aiming to balance performance, cost-efficiency, and long-term reliability, epoxy-bond wheels are more than an abrasive solution—they are a competitive advantage.

At CUMI, we partner with forward-thinking manufacturers to redefine grinding efficiency and precision. Our epoxy-bond wheels are built to last, built for performance, and built for leaders who demand more from their operations.

The question is no longer why switch—but how soon can you afford to?

Frequently Asked Questions

1) Where can I get CUMI’s epoxy bond grinding wheels?

The epoxy bond wheels are available through online enquiry on the website or email enquiry.

2) Why should I choose CUMI’s epoxy bond wheels over vitrified or resin bonds?

CUMI’s epoxy wheels offer greater flexibility, a superior and consistent finish, and longer operational life. They provide an exceptional combination of strength, durability, and thermal resistance.

3) What grinding applications benefit most from CUMI epoxy wheels?

Applications requiring fine tolerance, low heat generation, and burn-free grinding for hard-to-grind materials.

4) Are epoxy bond wheels suitable for precision and mass production?

Yes, their unique bonding system supports both high-precision operations and high-volume runs with minimal wear.

5) How should I select the right epoxy bond wheel for my process?

Consult with CUMI’s technical support for application-matched recommendations based on your workpiece and requirements.

Explore Our Products

Explore Our Products