Introduction: The Precision Demands of the Bearing Industry

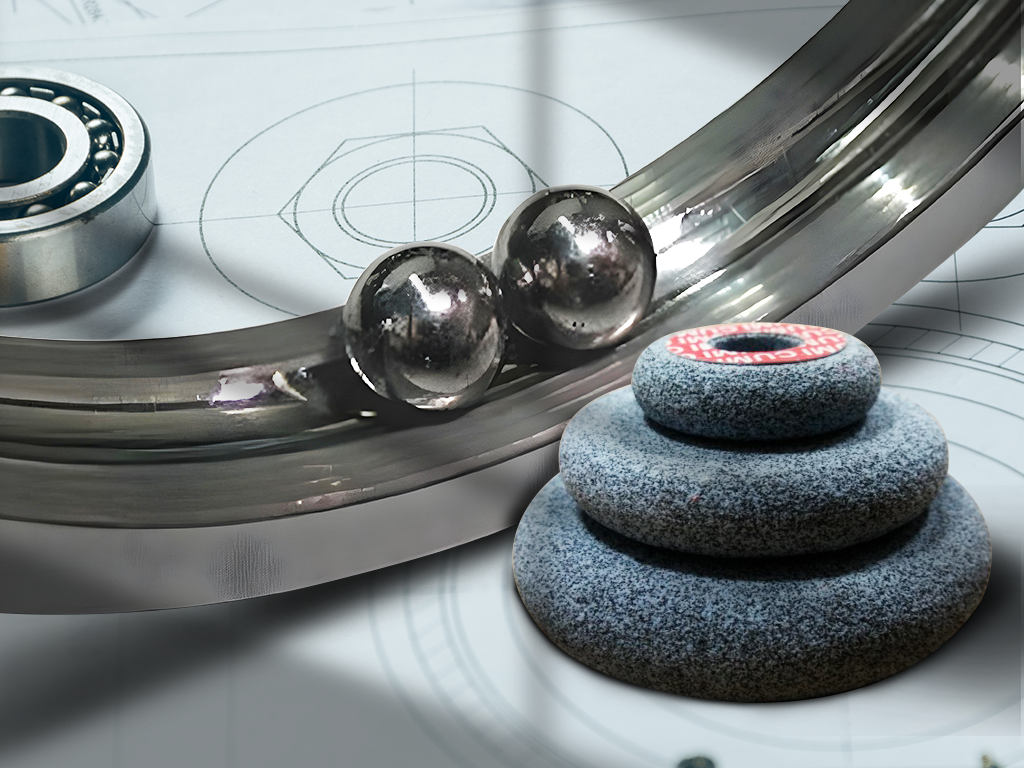

Q Bond Grinding Wheels play a crucial role in today’s fast-paced industrial ecosystem, supporting the bearing industry that powers machines from automotive to aerospace.As demands for performance, speed, and durability continue to rise, bearing manufacturers face an ever-growing challenge: achieving perfect geometry, superior surface finish, and consistent quality at scale.

Grinding plays a crucial role in this process, especially in outer race and bore grinding, where the tolerance levels are measured in microns. These are among the most critical and demanding operations in bearing production—where even the slightest surface imperfection or heat-induced stress can compromise the life and performance of the component.

The Industry Challenge: Precision Under Pressure

The materials used for bearing races, typically SAE 52100 steel, offer exceptional hardness (up to 64 HRC) but also pose unique challenges during grinding. Manufacturers must consistently achieve:

- Mirror-like surface finishes for smooth rotation

- High roundness and dimensional accuracy

- Minimal heat generation and burn-free surfaces

- Longer dressing intervals to improve productivity

However, real-world grinding operations often struggle with:

- Thermal damage due to high contact area and poor heat dissipation

- Wheel loading and dressing frequency, increasing downtime

- High power consumption, leading to energy inefficiency

- Cycle time constraints in high-volume production

These issues collectively affect production efficiency, cost, and final bearing performance.

Q Bond Grinding Wheel Technology

Understanding the evolving needs of the bearing industry, Carborundum Universal Limited (CUMI) developed the Q Bond series of grinding wheels—a next-generation innovation designed to address the toughest challenges in outer race and bore grinding applications.

Engineered through extensive R&D, the Q Bond wheel integrates:

- Surface-modified abrasive grains for controlled and consistent cutting action

- Micro-fracturing bond technology that renews cutting edges during operation

This synergy delivers measurable benefits in real-world grinding conditions:

- Extended dressing intervals for uninterrupted production

- Lower grinding power and reduced heat generation

- Superior surface finish and burn-free results

- Significant reduction in overall cycle time and grinding costs

Proven Results: Real-World Industry Applications

- Bore Grinding Application

In a leading bearing manufacturing setup, Q Bond outperformed the standard wheel by:

Parameter | Reference Wheel | Q Bond Wheel |

Surface Finish (Ra) | < 0.4 µm | < 0.35 µm |

Dressing Frequency (Components per Dress) | 15 | 60 |

Average Grinding Power (kW) | 1.27 | 1.07 |

Effective Grinding Time Reduction | – | 13–15% |

Result: 4× higher dressing interval, reduced power consumption, and smoother finishes—enabling cooler, more efficient bore grinding.

- Outer Race Grinding Application

For high-volume production lines, Q Bond enabled faster grinding while maintaining quality:

Parameter | Reference Wheel | Q Bond Wheel |

Surface Finish (Ra) | < 0.5 µm | < 0.5 µm |

Dressing Frequency (Components per Dress) | 2 | 8 |

Total Cycle Time (Seconds) | 11.1 | 9.6 |

Result: Nearly 14% cycle time reduction with consistent finish and geometry—ideal for precision, high-output manufacturing.

Why Q Bond Makes the Difference

Q Bond wheels are designed for high-efficiency material removal with lower energy input. Their unique structure ensures:

- Burn-free grinding even under high loads

- Excellent roundness retention

- Longer wheel life and reduced dressing downtime

- Lower total cost per component

Conclusion: Empowering the Future of Bearing Manufacturing

With the Q Bond series, CUMI is redefining grinding performance standards in the bearing industry. Built on advanced material science and deep process understanding, Q Bond delivers superior quality, productivity, and energy efficiency—helping manufacturers meet the precision demands of today’s machines while preparing for the technologies of tomorrow.

Frequently Asked Questions

1: Where can I buy Q Bond grinding wheels for bearing industry use?

The Q Bond grinding wheels are available through online enquiry on the website or email enquiry.

2: Why should I choose CUMI’s Q Bond grinding wheels over other brands?

CUMI’s Q Bond wheels feature advanced grain and bonding technology, Lower total cost per component, longer life, and minimal dressing downtime.

3: How do Q Bond wheels prevent thermal damage during grinding?

Their surface-modified grains and micro-fracturing bond technology dissipate heat efficiently and avoid burns on workpieces.

4: What materials are best suited for Q Bond wheels?

Q Bond wheels excel in grinding hard bearing steels like SAE 52100, especially for bore and outer race applications.

5: How does using Q Bond wheels improve productivity and cost efficiency?

Extended dressing intervals, reduced power consumption, and lower cycle times improve productivity and cost efficiency per component.