The Science of Grinding Smarter: How Advanced Alumina Wheels Slash Cycle Time

By Ashish Kumar Gupta, Global Bearing Segment Manager

Walk into any modern bearing manufacturing line—whether at SKF, Timken, NEI, or Schaeffler—and you’ll see grinding machines humming away, shaping the final quality of critical components. What you won’t see is the mathematical truth that determines whether that line is truly productive or quietly losing money. It’s captured in one elegant formula:

t_cycle = (TG + TD) / N

In plain terms, the time a machine spends making each part depends not just on grinding time (TG), but on something manufacturers often underestimate: how often the wheel needs to be dressed (TD), and how many parts it can produce before the next dressing (N).

When N is low, dressing overhead gets piled onto every part. When N stretches higher, that overhead spreads thinly, and productivity rises almost automatically. It’s a rare moment where math and manufacturing speak the same language: increase N and the entire process gets faster.

But there’s more at stake than cycle time. For bearing manufacturers facing intense global competition, the real question is, “How do we reduce cost per component while maintaining the precision our customers demand?“

The Hidden Cost of Dressing in Bearing Production

Every dressing operation restores sharpness and geometry, but it also stops production. Machines sit idle. Wheel life drops. Cost per component quietly climbs. Avoid dressing for too long, and you invite glazing, rising forces, and thermal damage—especially critical when grinding hardened bearing steels like 52100 or carburized components. For production managers and grinding engineers in the bearing industry, this creates a constant tension: dress too often and lose productivity; dress too infrequently and risk quality issues that could mean scrapped parts or, worse, field failures.

The ideal scenario is obvious: a wheel sharp enough and stable enough to keep cutting cleanly for longer intervals, allowing N to rise without sacrificing the tight tolerances bearing applications demand.

CUMI Advanced Alumina: Engineered for Bearing Applications

CUMI’s advanced alumina wheels have been designed specifically to address the dressing bottleneck that bearing manufacturers face daily. The ceramic alumina grains feature a controlled micro-fracture mechanism. Unlike conventional abrasives that dull uniformly, these grains reveal fresh, sharp cutting edges throughout the operation. Think of it as self-sharpening technology at the microscopic level.

The bond structure is equally critical. CUMI engineers have crafted a vitrified bond system that balances strength with porosity, allowing better chip clearance and easier coolant access to the grinding zone. In bearing grinding, where you’re often working with difficult-to-grind materials at high removal rates, effective coolant delivery directly impacts both wheel life and workpiece quality.

The result is a wheel that:

- Stays sharper for longer periods

- Holds its form under demanding loads

- Runs cooler even at elevated removal rates

- Extends the N value naturally

In practical terms for bearing production, this means N increases while surface finish, dimensional accuracy, and form tolerance remain consistent.

Proven Results in Leading Bearing Plants

Bearing manufacturers are data-driven by necessity. When we work with bearing plants—from automotive suppliers to industrial bearing producers—the results are consistently measurable.

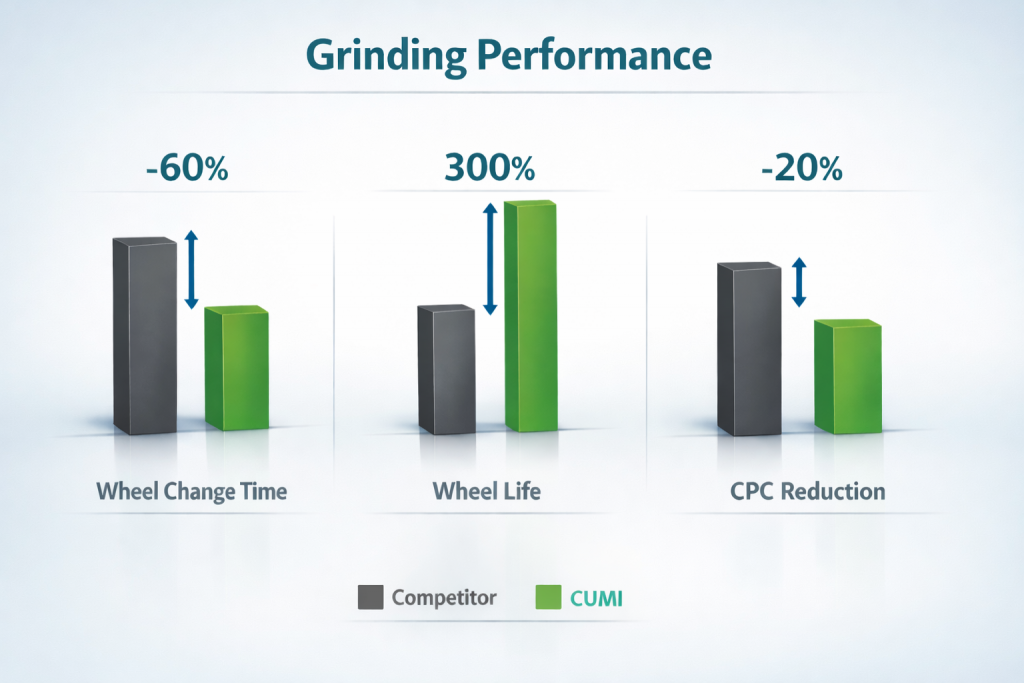

Manufacturers across automotive and bearing applications using CUMI advanced alumina wheels report:

Wheel Change Time: 60% Reduction

Faster changeovers mean less downtime. When you’re running multi-shift operations, those minutes add up to hours of additional production time per month.

Wheel Life: 300% Improvement

Extended wheel life means fewer wheel purchases, fewer changeovers, more consistent process, and a higher N value.

Cost Per Component: 20% Reduction

This is the metric that matters most to plant managers. Twenty percent cost reduction in grinding operations can significantly impact overall manufacturing profitability, especially in high-volume bearing production.

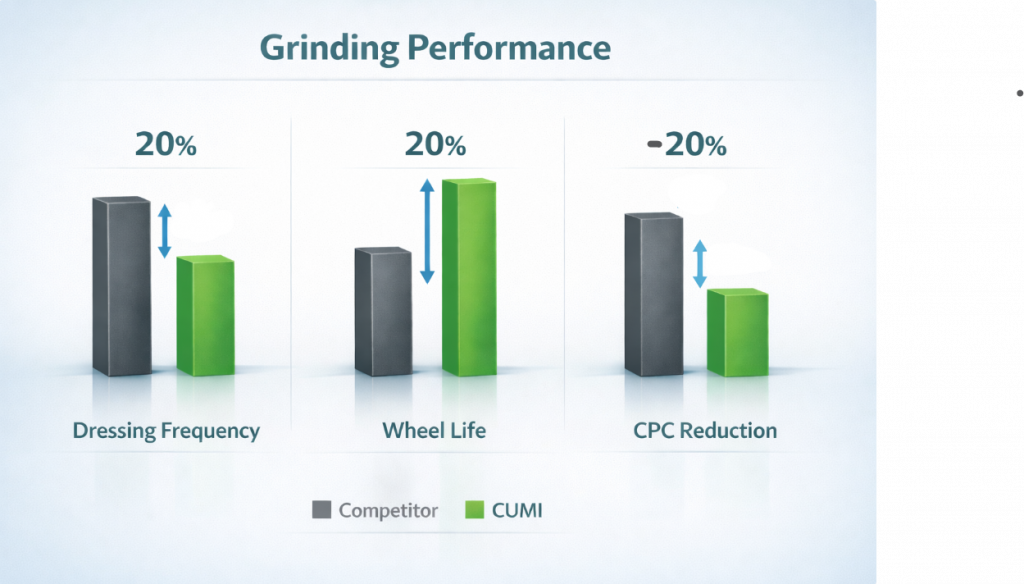

Beyond the dramatic wheel life improvements, CUMI alumina wheels deliver consistent performance across key operational metrics. The data shows 20% improvement in dressing frequency and 20% enhancement in overall wheel life stability, translating directly to more predictable production schedules and lower total grinding costs.

These aren’t isolated results from a single trial. These performance improvements have been documented across multiple bearing manufacturers, different applications (cylindrical grinding, through-feed grinding, surface grinding), and various workpiece materials.

Why Bearing Manufacturers Choose CUMI

The bearing grinding market has several established suppliers—Tyrolit, GNL, Noritake, Meister, and others. What makes bearing manufacturers switch to CUMI?

Consistent, Repeatable Performance

Bearing grinding isn’t about achieving extraordinary results once—it’s about delivering the same precision across thousands of components, shift after shift. CUMI’s advanced alumina technology delivers this consistency because the micro-fracture mechanism is engineered into the grain structure itself.

Comprehensive Technical Support

Having worked with bearing manufacturers for over 15 years, including time as part of SKF’s grinding community, I’ve seen that wheel selection is just the beginning. The real value comes from understanding your specific grinding parameters, workpiece materials, machine capabilities, and quality requirements.

Total Value Beyond Price

Bearing manufacturers consistently tell us their primary pain point is cost per component. A cheaper wheel that requires more frequent dressing, wears out faster, and delivers inconsistent quality actually costs more in the end. CUMI’s value proposition addresses the total cost equation through lower cost per component, reduced downtime, consistent quality, and technical support that helps optimize the entire grinding process.

Expert Insight: 15 Years of Bearing Grinding Optimization

Over my career in bearing grinding—from working within SKF’s grinding community to serving as CUMI’s Global Bearing Segment Manager—I’ve led more than 20 grinding optimization projects across major bearing manufacturers.

Key insights from these projects:

The 10% Cycle Time Barrier: Many manufacturers believe 5% cycle time improvement is good. We’ve consistently achieved 10% or better by focusing on the entire grinding equation, not just wheel speed or feed rate.

The Productivity-Quality Balance: The best grinding processes don’t sacrifice one for the other. With the right wheel technology, you can improve both simultaneously.

The Hidden Costs: Most manufacturers track wheel cost carefully but underestimate the cost of downtime, scrap, and operator time spent on changeovers and troubleshooting.

The Power of Partnership: The most successful grinding operations view their abrasive supplier as a technical partner, not just a vendor.

Taking the Next Step

Grinding improvement begins with understanding TG, TD, and N in your specific operation. The next step is selecting wheel technology built to support a higher N value while maintaining the quality your bearing customers demand.

With CUMI advanced alumina wheels, the formula becomes more than a calculation—it becomes a reliable path to better productivity, lower costs, and more consistent quality.

Whether you’re grinding components for automotive bearings at SKF, industrial applications at Timken, or specialized bearings at NEI or Schaeffler, the fundamentals remain the same: the right abrasive technology makes a measurable difference in your bottom line.

CUMI: Tomorrow’s victories can’t be won with yesterday’s products. We deliver advanced grinding solutions for greater productivity.

About the Author

Ashish Kumar Gupta

Global Bearing Segment Manager, CUMI

Ashish Kumar Gupta brings over 15 years of specialized expertise in bearing grinding processes to his role as CUMI’s Global Bearing Segment Manager. With qualifications in Mechanical Engineering (BE), Operations Management (MBA), and Quality Management Systems (M.Tech), Ashish combines engineering knowledge with practical manufacturing experience.

As a former member of SKF’s grinding community and Subject Matter Expert in Grinding and Honing Processes, Ashish has led over 20 successful grinding optimization projects across major bearing manufacturers. His systematic approach to process improvement has delivered measurable results: 10% cycle time reduction, 20% productivity improvements, and 20% cost per component savings for clients worldwide.

Connect with Ashish: LinkedIn Profile