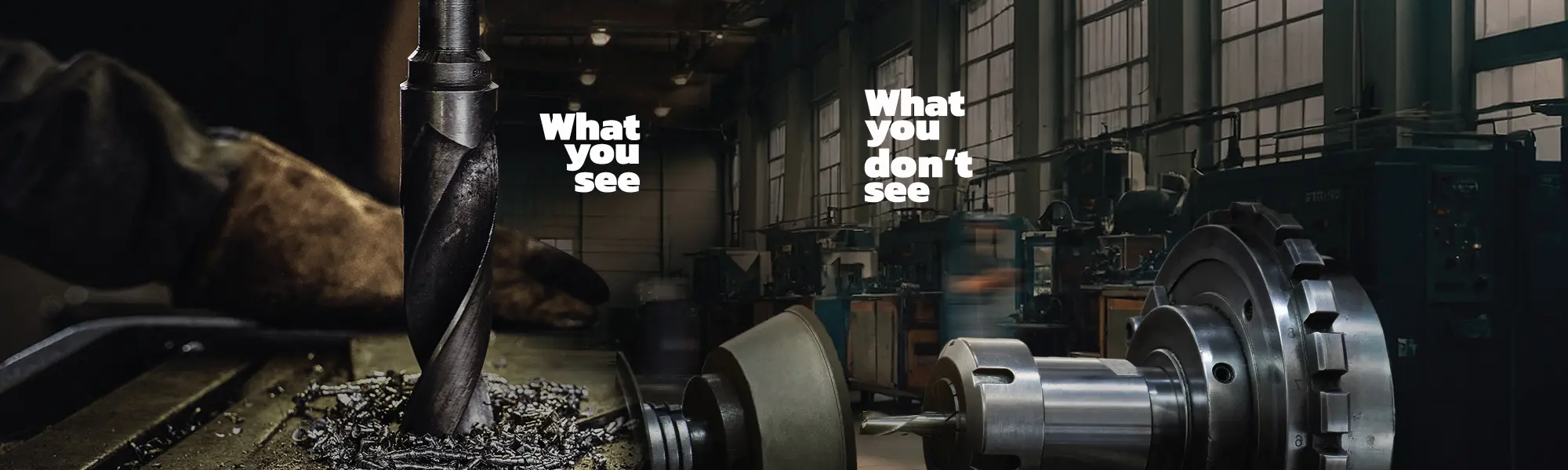

Whether producing drill bits, reamers, milling cutters, or custom tool profiles, achieving precise geometry and optimal cutting edges depends on controlled grinding. From shaping drills and taps to finishing hobs, inserts, and milling cutters, CUMI’s cutting tool abrasives maintain form integrity, achieve exact geometries, and support the high-performance standards demanded in modern machining.

Shapes, sharpens, and finishes cutting tools to meet precise dimensional and edge quality requirements.

Product Options:

Cylindrical grinding

Centerless grinding

Flute grinding

Thread grinding

Surface grinding

Internal grinding

Wheels are manufactured for both standard and complex tool geometries.

Guidance from CUMI’s technical team to fine-tune grinding parameters.

Rapid on-site or remote support for grinding wheel failures or downtime.

Every product meets stringent international manufacturing standards.

Coarser grits are suited for heavy stock removal, while finer grits produce a perfect profile, cleaner edge and surface. The choice depends on tool material, design, and production targets. CUMI provides grit recommendations tailored to each application.

Edge chipping can result from using the wrong bond type, excessive feed rates, or poor coolant application. CUMI’s resin and vitrified wheels are engineered to reduce mechanical stress on tool edges.

While possible, it’s more efficient to use separate wheels — a coarser grit for stock removal and a finer grit for finishing. CUMI can recommend optimal grit combinations based on your cycle time and finish requirements.

For carbide tool manufacturing, silicon carbide wheels are most effective due to their hardness and cool cutting. CUMI offers resin bond and vitrified bond diamond wheels designed for superior edge quality and minimal chipping.

If you face problems like wheel failure, uneven wear, or sudden downtime, CUMI’s technical team can assess your process and recommend the right solution to restore performance quickly.

Adding {{itemName}} to cart

Added {{itemName}} to cart