Introduction

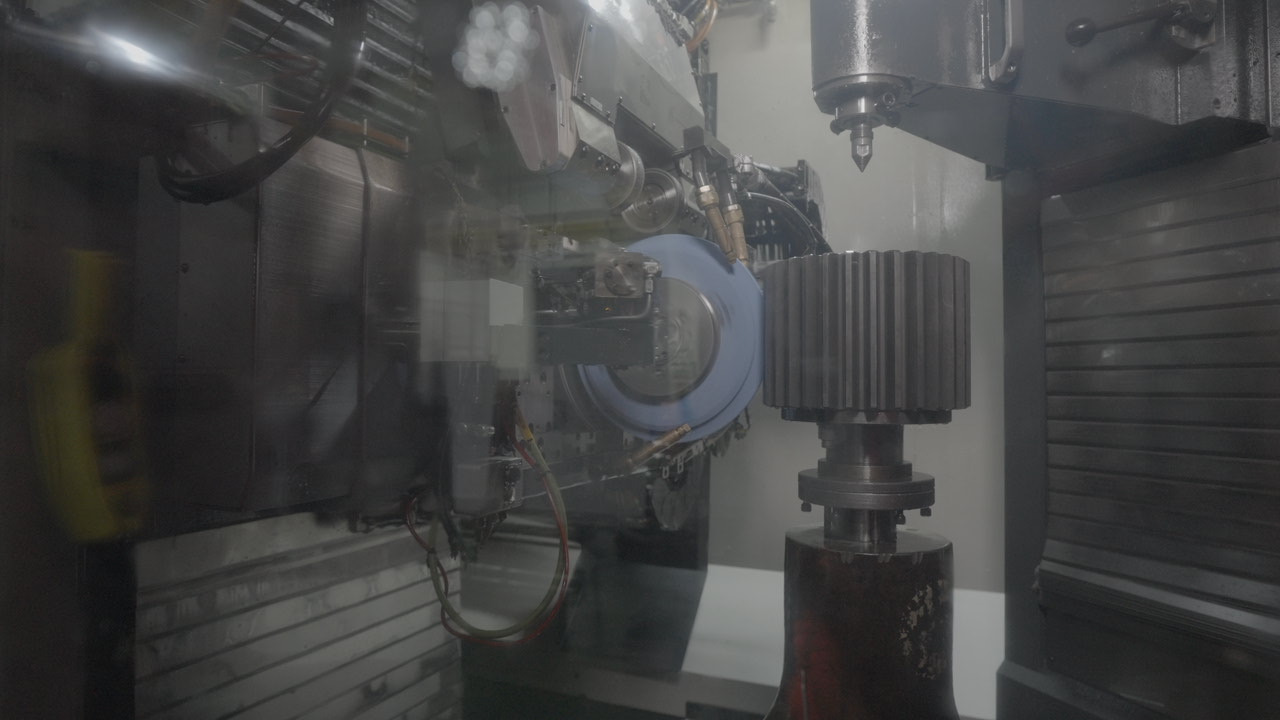

When you think of auto part manufacturing, you might imagine high-tech robots or precision-engineered parts. But behind every smooth finish, exact fit, and flawless surface lies an unsung hero — abrasives. From grinding crankshafts to polishing gear components, abrasives are essential to every stage of auto part production. Let’s explore how these powerful tools play a pivotal role in shaping the future of the automotive industry.

1. Precision That Drives Performance

In the automotive aftermarket, precision is everything. Components like brake pads, gears, and bearings must fit and perform flawlessly. Abrasives ensure micron-level accuracy through:

- Surface grinding

- Cylindrical grinding

- Deburring and finishing

We at CUMI engineer our automotive abrasive solutions to handle complex geometries and tight tolerances, resulting in smoother engine performance and longer part life.

👉 Explore Auto Ancillary Abrasive Solutions

2. Cost-Effective Finishing for Mass Production

Auto part manufacturers face the challenge of maintaining consistent quality at high volumes. CUMI’s bonded and coated abrasives provide:

- High material removal rates

- Long-lasting tool life

- Reduced dressing and changeover times

This means fewer breakdowns, faster turnaround, and better margins.

3. Boosting Surface Integrity for Safety

Safety components such as brake rotors and transmission parts depend on flawless surfaces. Our abrasive wheels, belts, and finishing tools help:

- Remove surface cracks

- Improve fatigue resistance

- Enhance adhesion for coatings or bonding

With CUMI’s advanced abrasive systems, manufacturers meet safety standards without compromising speed or cost.

4. Customized Solutions for Every Vehicle Type

Whether it’s a two-wheeler, passenger car, or heavy-duty truck, CUMI provides tailored abrasive solutions. Our R&D-backed innovation ensures:

- Application-specific grit sizes and bonds

- High-performance materials like ceramic abrasives

- Compatibility with automated production lines

Check our full Transmission Component Finishing Guide → Read more

5. Sustainability in Surface Finishing

Today’s auto industry is moving toward greener production. CUMI supports this with:

- Eco-friendly manufacturing of abrasives

- Durable products that reduce waste

- Energy-efficient grinding systems

Our abrasives help you meet environmental compliance while maintaining world-class quality.

Conclusion: Don’t Overlook the Invisible Contributor

Abrasives may not be the most visible component in the auto parts supply chain, but they are certainly one of the most critical. From rough shaping to fine finishing, they power the processes that keep vehicles running smoothly and safely.

If you’re in the auto aftermarket and looking for precision, efficiency, and quality, partner with CUMI Abrasives — the name trusted by automotive leaders across the globe.

Frequently Asked Questions

1) Where can I order CUMI abrasives for auto parts manufacturing?

Order through CUMI’s authorized dealers or directly from their website for specialized, high-performance abrasives.

2) Why do automotive companies select CUMI for grinding and finishing?

CUMI abrasives deliver the precision, durability, and expert technical or sales engineer support vital for auto part performance and compliance.

3) What types of abrasives are commonly used in the automotive sector?

Grinding wheels, sanding discs, and specialty finishing products tailored for metals and composites.

4) How do abrasives enhance the durability and performance of auto components?

Precision grinding and finishing eliminate defects, ensure tight tolerances, and extend functional life.

5) How do I choose the proper abrasive for my automotive application?

Consider your part material and finish requirements, or consult CUMI’s expert application engineers for guidance.