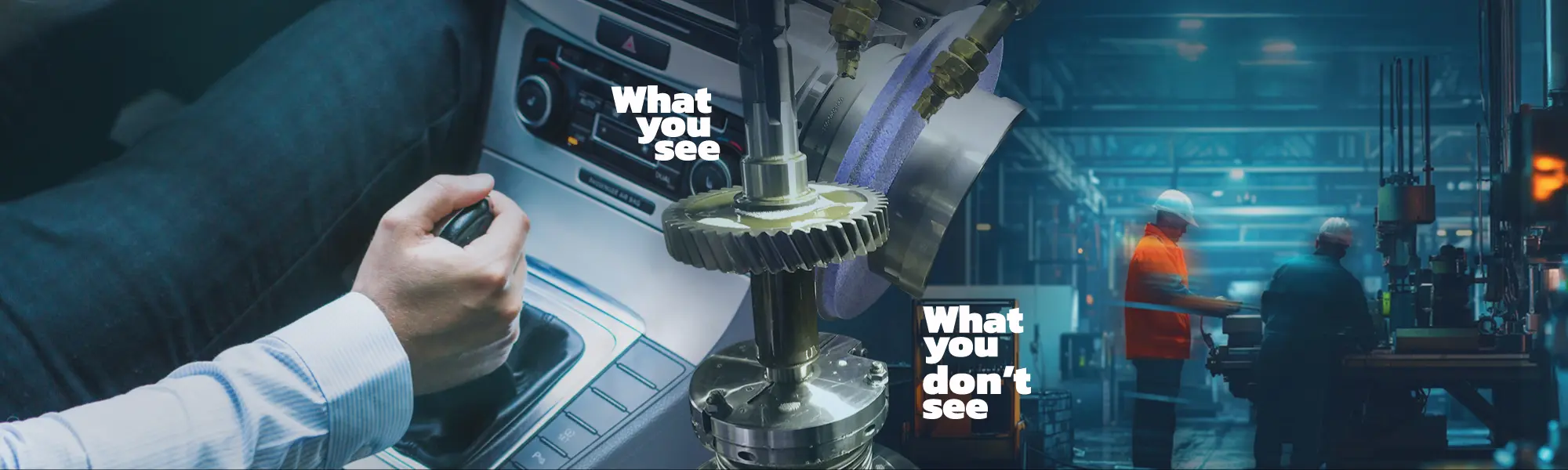

From automotive drivetrains to heavy industrial gearboxes, transmission components rely on flawless tooth geometry and surface integrity.

CUMI’s precision gear grinding abrasive solutions ensure exact tooth profiles, smooth flank finishes, and exceptional dimensional stability—minimising wear, heat build-up, and vibration. Suitable for spur, helical, and bevel gears, our abrasives help gearmakers achieve longer-lasting, higher-performing components.

Maintains profile accuracy and pitch consistency across batches, ensuring gears run efficiently and mesh perfectly in service.

Product Options:

Gear Profile Grinding

Gear Generative Grinding

Gear Bevel Grinding

Shaft Worm grinding

Shaft Cylindrical grinding

Gear Internal Grinding

Shaft Centreless Grinding

Shaft Angular grinding

Keeps gear shapes accurate even in prolonged production runs.

Tailored products for honing, shaping, and finish grinding processes.

48–62 Hour Technical Response. Rapid on-site or remote support for grinding wheel failures or downtime.

Exact tooth profiles and highly polished finishes for efficient, noise-free performance.

Using CUMI wheels with controlled wear characteristics and stable bonds minimises heat build-up, helping maintain tooth profile and pitch accuracy.

Precision grinding ensures surface is uniform, accurately shaped, and smooth. This reduces friction, minimises noise, and extends gear components life. CUMI’s precision grinding wheels are engineered for tight tolerances and form stability, making them ideal for producing high-performance gears.

If production stops due to wheel damage or performance issues, CUMI’s technical team addresses and resolves the problem within 48–62 hours, ensuring minimal downtime.

Yes. Whether you need wheels for spur, helical, bevel, or special gear forms, CUMI designs customised solutions with the right bond, grit size, and wheel geometry to match your exact application.

Switching to a fine-grit wheel with a stable bond system can achieve a smoother finish while maintaining accuracy. CUMI’s cork-bond wheels are specifically designed for achieving a refined, low-surface finish.

When selecting a grinding wheel for precision work, focus on these key factors:

Adding {{itemName}} to cart

Added {{itemName}} to cart