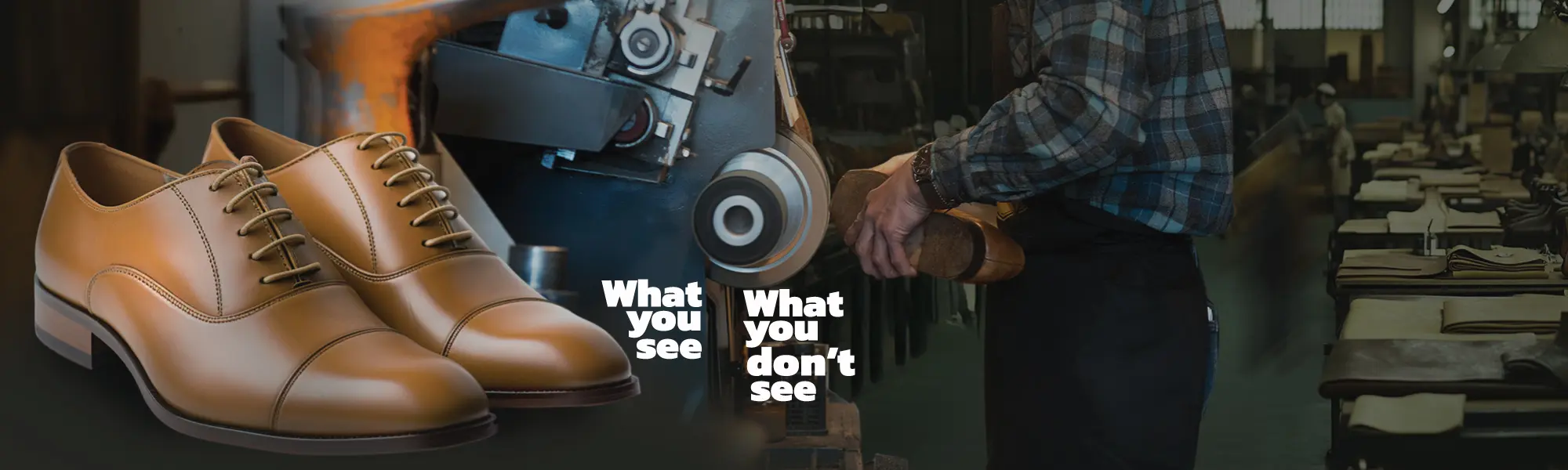

From high-end footwear to premium upholstery, the leather industry demands flawless finishes and delicate handling. CUMI’s leather abrasive solutions are designed to deliver controlled performance for buffing, polishing, and smoothening — essential for soft-touch surfaces and consistent texture.

Whether you’re refining grain leather or preparing hides for cutting and stitching, our abrasives help ensure every step adds value without compromising quality.

Visit our dedicated partner platform for detailed product information, technical specs, and leather-specific abrasive solutions.

www.awukoabrasive.com

Elevates natural shine, refines finishes, and enhances visual appeal.

Product Options:

Removes blemishes and minor marks for a uniform, smooth surface.

Product Options:

Creates soft, even textures by eliminating surface irregularities and preparing hides for finish coatings.

Product Options:

Achieve smooth matte feel and gloss levels across extended production runs.

Abrasives adapted to leather hardness, finish type, and production method.

CUMI abrasives are already integrated into top global supply chains in leather footwear, fashion goods, and upholstery.

Expert guidance on process parameters and abrasive choices specific to hide type and finish outcome.

Fluffing usually occurs due to either:

To fix this, switch to a finer-grit abrasive (280–400) and reduce pressure. Use CUMI's flexible leather abrasives, designed to trim clean edges while maintaining leather fiber integrity. Adding a light edge sealer post-sanding also helps lock in the fibers.

Clogging often results from:

Solution: Opt for open-coated abrasive belts that reduce loading. CUMI’s Aluminium oxide wide belts are treated to resist clogging and improve airflow, making them ideal for oily or waxy hides. Routine belt cleaning also extends lifespan.

Yes, if using abrasives with high aggressiveness or incorrect backing. To preserve fine detailing:

Typically, 220 to 400 grit abrasives are used for pre-finish buffing, depending on the leather type and intended finish. Coarser grits remove inconsistencies, while finer grits prep the surface for top coats or polishing. CUMI provides custom grit configurations based on processing speed and leather grade.

Lifespan depends on hide type, pressure applied, and process speed. On average, CUMI’s leather abrasives deliver 15–20% longer life compared to generic products, with minimal clogging and uniform performance across batches.

Adding {{itemName}} to cart

Added {{itemName}} to cart