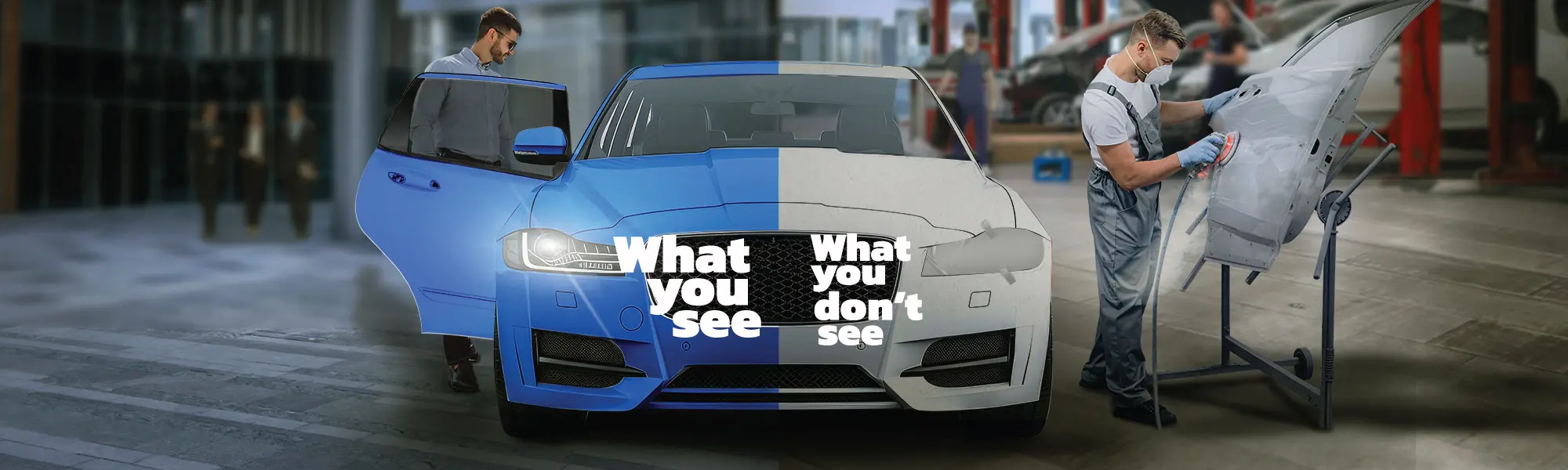

Every vehicle that enters the workshop deserves to leave with a finish that speaks quality. At CUMI, we support the complete end-to-end vehicle refinishing cycle—from cutting and sanding bare metal to delivering that high-gloss, paint-ready surface. CUMI SHINELINE automotive vehicle refinishing abrasives are exclusively designed for longevity, a stunning glossy finish and smooth transitions to achieve professional-grade results.

Better

Better

Used for shaping fillers, contour sanding, putty filler sanding and preparing surfaces for paint. Delivers high-end surface finish with 30% longer life and uniform scratch patterns.

Product Options:

Suitable for panel cutting, removing heavy welds and rust. Delivers high stock removal with minimal surface damage and up to 30% faster action.

Product Options:

Removes fine surface imperfections and haze from painted or coated areas. Enables a smooth, reflective base before final buffing.

Product Options:

Delivers reliable scratch depth across grits, ensuring smooth transitions & stunning finish between each stage.

CUMI abrasives are built to withstand long production cycles with minimal wear, reducing changeovers.

Custom grit combinations, disc sizes, and bonds are designed to match specific machines, materials, and finish goals.

Designed to conform to curves, edges, and contours—ideal for modern vehicle designs.

For a smooth, defect-free finish, grit selection should follow each surface preparation stage:

Clogging happens due to resin dust and soft filler buildup. Use open-coat abrasives with anti-loading treatment, and avoid excess pressure. CUMI’s coated abrasives are designed to stay clean longer.

Use a consistent cross-hatch sanding technique and step down through finer grits before moving to polishing compounds. Avoid skipping grits. Finish with a fine buffing abrasive to eliminate micro-scratches.

No. Using the wrong abrasive type for wet sanding can cause grain shedding, delamination, or surface defects. Many garage workers assume dry-use abrasives can be sprayed with water—this leads to early failure and uneven finish.

Premature wear is often caused by poor filler compatibility or over-application pressure. Heavy body fillers can quickly clog standard abrasives, reducing cutting action. Other causes include low-quality grain bonding and incorrect grit choices for rough shaping.

Over‑sanding is a pervasive issue in bodyshop work. It makes panels and filler areas thin which can lead to adhesion failure and visible defects after painting.

Best practice:

Adding {{itemName}} to cart

Added {{itemName}} to cart