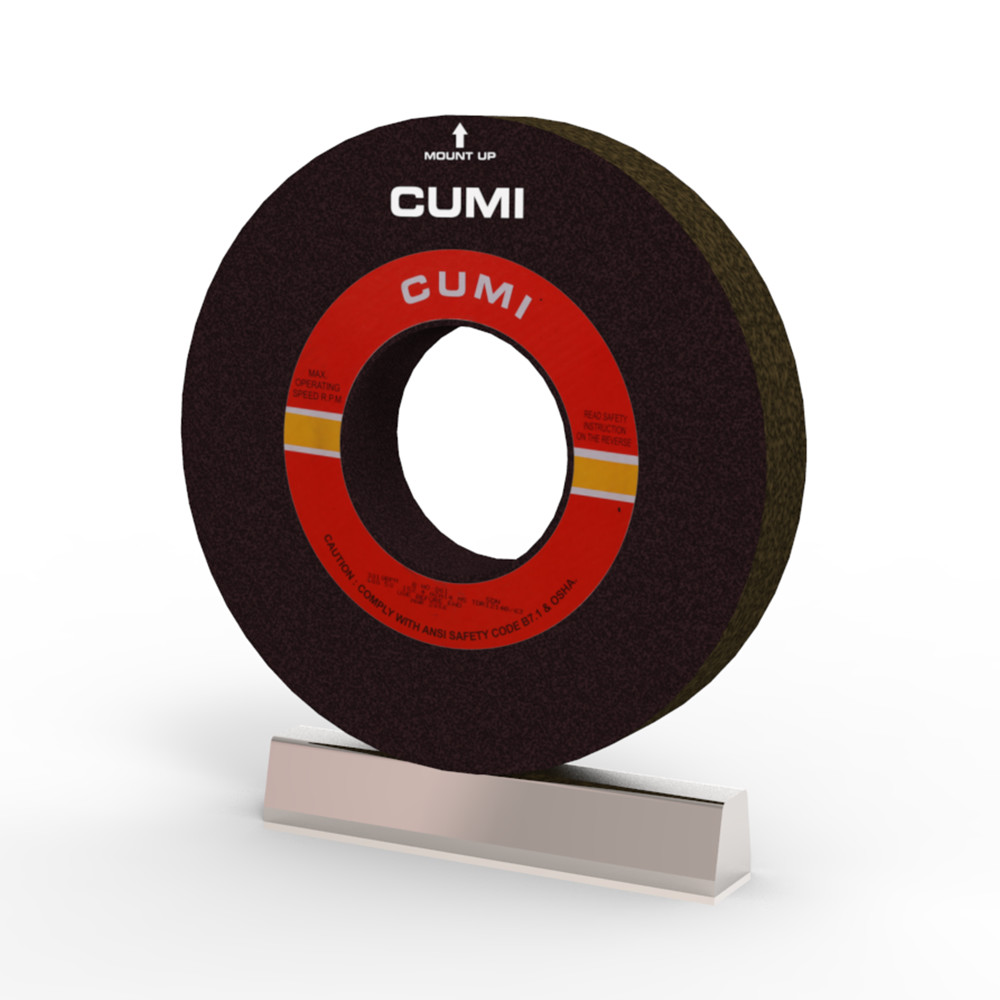

Product description

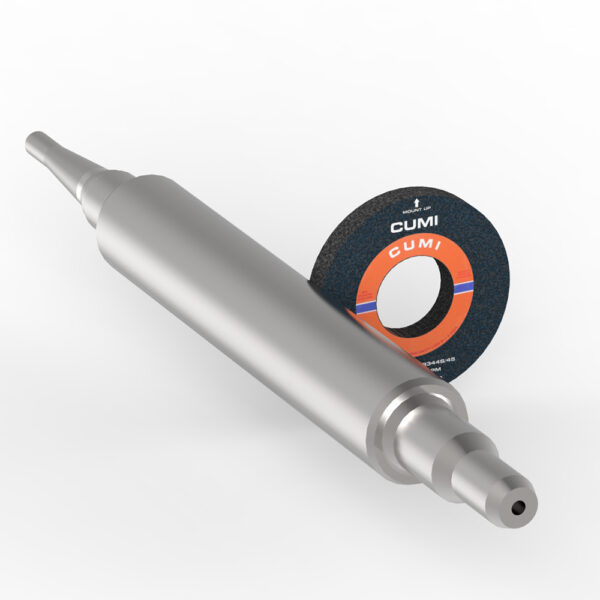

Although a simple cylindrical grinding application, what makes Roll grinding challenging is the volume of stock removed from rolls, which are difficult to grind. The length of roll also provides a challenge for the wheel to retain its size and form during the traverse grinding process. Maintaining high grinding ratios/ roll reduction values is crucial in these applications, as they have a direct effect on the overall cost and cycle time.

CUMI Roll Grinding wheels combine the latest developments in resin bond technology along with suitable grain combination to give the optimal balance between cutting action and wheel life without compromising on the quality parameters.

Features:

- Hi performnace Microcrystalline abrasive blended with silicon carbide grains

- Special phenolic resins for high wear resistance

- modular manufacturing facility

- Controlled curing process

Advantages:

- High feed rates for faster cycle times

- Controlled wear (High Grinding ratios)

- Excellent surface quality

- Spiral & Scratch free finsih for cold rolling applications

- Consistent performance throughout working life

| Abrasive Used | CUMI Code | Grit | Diameter (mm) | Diameter (Inch) | Thickness (mm) | Thickness (Inch) | Speed | Hardness | Structure |

|---|---|---|---|---|---|---|---|---|---|

| Ceramic Aluminium Oxide | CE | 36 - 120 | 610 - 1100 | 24-1/64 to 43-5/16 | 60 - 150 | 2-23/64 to 5-29/32 | 45 | I - K | 5 - '7 |

| Semi-Friable Grain | SA | ||||||||

| White Aluminium Oxide | AA | ||||||||

| Brown Aluminium Oxide | A | ||||||||

| Green Silicon Carbide | GC |

| Type of Roll | Speed | Best | Better | Good |

|---|---|---|---|---|

| Work Roll | 50 | 3CE30 J6 B1363/50 | GC361 B112R 4 | |

| Back up Roll | 3CE30 J6 B1363/50 | - | A30 J5 B384 |

| Type of Roll | Speed | Best | Better | Good |

|---|---|---|---|---|

| Work Roll | 50 | 3CE60 K5 B384R | DA60 K5 B384R/50 | A60 K5 B384 |

| Back up Roll | - | DA46 J5 B384R | A46 J5 B384 |

CUMI Bonded Abrasives Catalogue

CUMI Bonded Abrasives Catalogue