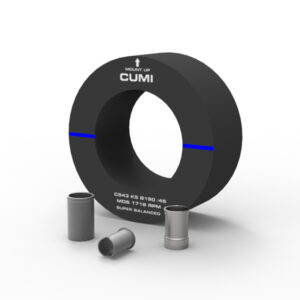

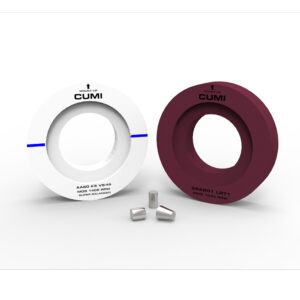

Centerless Grinding Wheels

Product description

An application which presents the most daunting challenges to any abrasive manufacturer. The range of requirements and priorities of this application varies from product to product which calls for an equally wide range of offerings to suit the same.

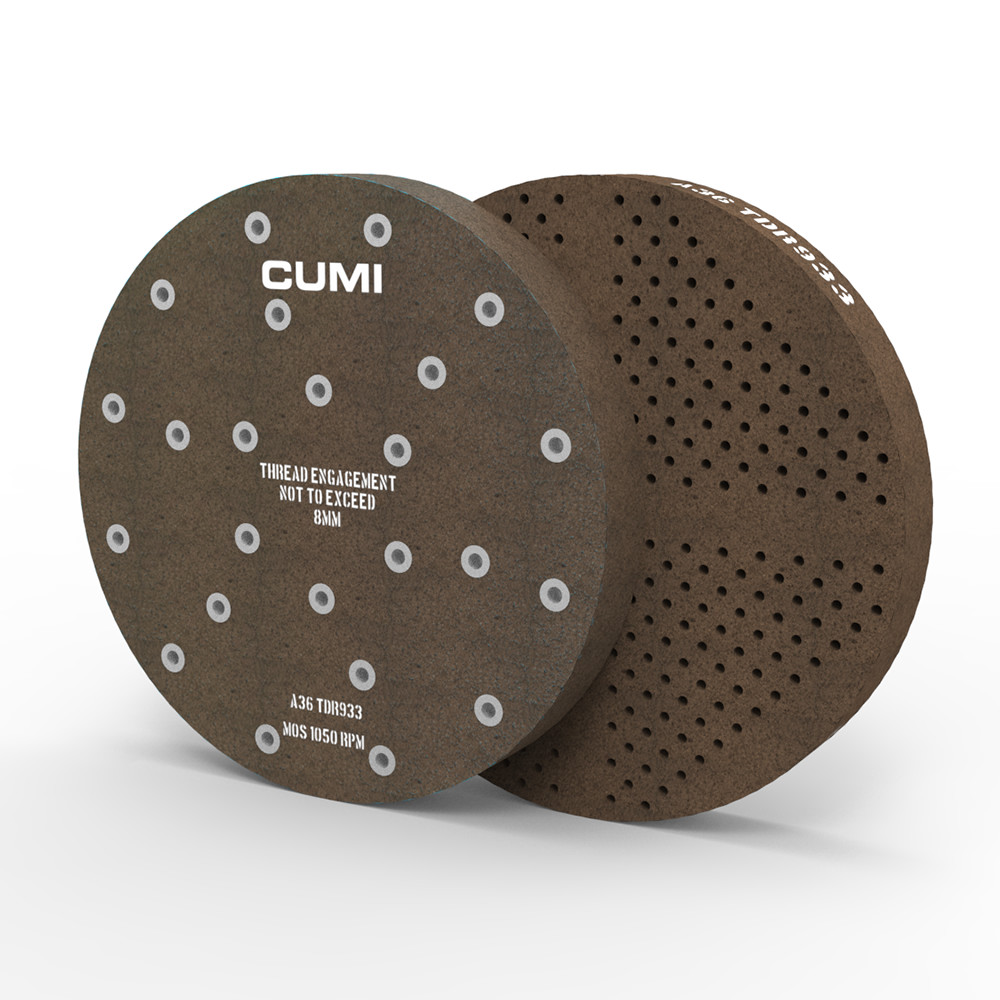

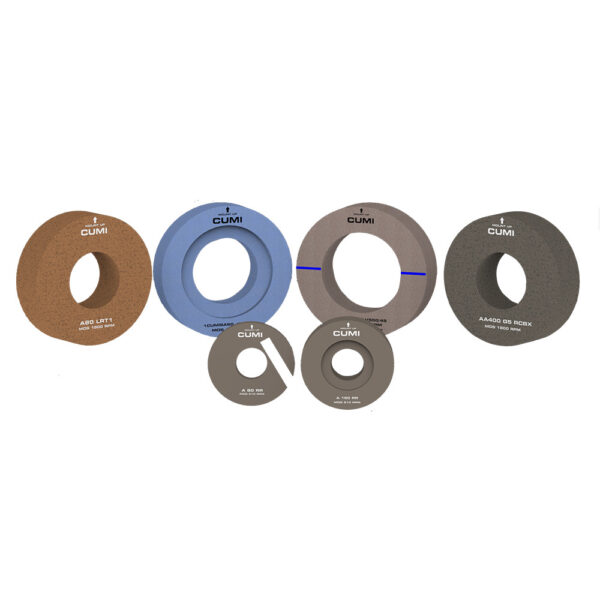

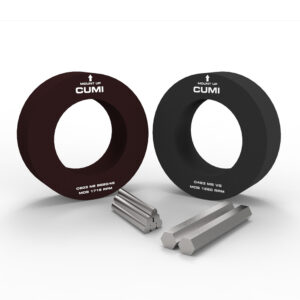

Since in most of the Centerless applications, more than one wheels is mounted on the spindle, extremely tight tolerances need to be maintained in the geometry and densities of the wheels to ensure uniform wear patterns even if each wheel in the set is different.

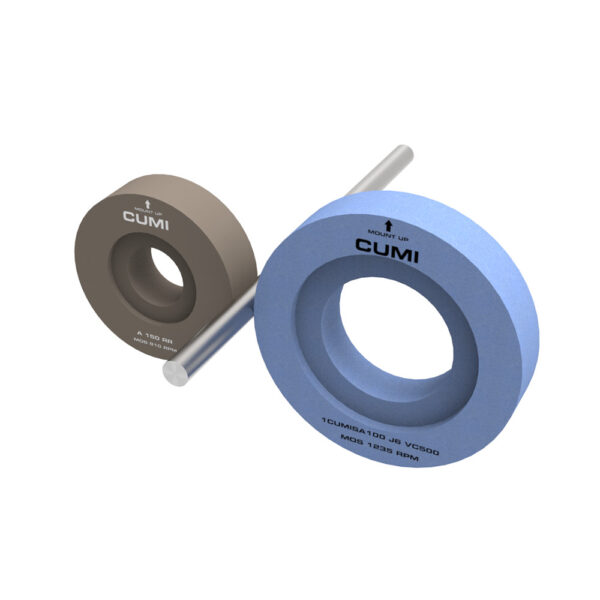

CUMI has the expertise, when it comes to Centerless applications thanks to the advanced manufacturing process, premium Abrasive grains and specially designed Vitrified, Resin and Rubber bond systems to suit the application needs. Customized solutions are provided for every application and specific requirement.

Be it through-feed, end-feed or in-feed CUMI wheels ensure that components are finished to stringent quality requirements.

Features:

- Unique set of combination wheels for higher stock removal, good surface roughness and higher productivity

- Unique grain combination for specific application

- Cork bond for superior surface roughness & lustre

- Wide range of bond system to customize individual grinding needs

Advantages:

- High stock removal

- Lower dressing frequency

- Burn free component

- Better productivity

- Excellent surface finish

| Abrasive Used | CUMI Code | Grit Range | Diameter (MM) | Diameter (Inch) | Thickness (MM) | Thickness (Inch) | Hardness | Structure | Speed (MPS) |

|---|---|---|---|---|---|---|---|---|---|

| Ceramic Aluminium Oxide | CUMISA | 46 - 120 | 350 - 610 | 14 - 24 | 100 - 250 | 4 - 10 | I - N | 6 & 8 | 35. 50 & 63 |

| Sharp Aluminium Oxide | 53A / 55A | 46 - 120 | 350 - 610 | 14 - 24 | 100 - 250 | 4 - 10 | I - N | 7 | 35 & 50 |

| Premium Aluminium Oxide | 65A | 80-220 | 350 - 610 | 14 - 24 | 100 - 250 | 4 - 10 | L | - | 40 |

| Semi-Friable Aluminium Oxide | SA | 46 - 120 | 350 - 610 | 14 - 24 | 100 - 250 | 4 - 10 | I - N | 5 - 7 | 35 & 50 |

| 9A | 46 - 120 | 350 - 610 | 14 -24 | 100 - 250 | 4 - 10 | I - P | 5 - 7 | 35 & 50 | |

| SBA | 46 - 120 | 350 - 610 | 14 -24 | 100 - 250 | 4 - 10 | I - P | 5 - 7 | ||

| White Aluminium Oxide | AA | 46 - 120 | 350 - 610 | 14 - 24 | 100 - 250 | 4 - 10 | I - N | 5 - 7 | 35 & 50 |

| Aluminium Oxide Blend | DA | 46 - 120 | 350 - 610 | 14 - 24 | 100 - 300 | 4 - 12 | I - P | 5 - 7 | 35 & 50 |

| Brown Aluminium Oxide | A | 46 - 120 | 350 - 610 | 14 - 24 | 100 - 300 | 4 - 12 | I - P | 5 - 7 | 35 & 50 |

| Black Silicon Carbide | C | 46 - 120 | 350 - 610 | 14 - 24 | 100 - 300 | 4 - 12 | I - P | 5 - 7 | 35 & 50 |

| Green Silicon Carbide | GC | 46 - 120 | 350 - 610 | 14 - 24 | 100 - 300 | 4 - 12 | I - N | 5 - 7 | 35 & 50 |

Bonded Centreless Grinding Catalogue

Bonded Centreless Grinding Catalogue