- Chopsaw

- Coated Abrasives

- Core Drills

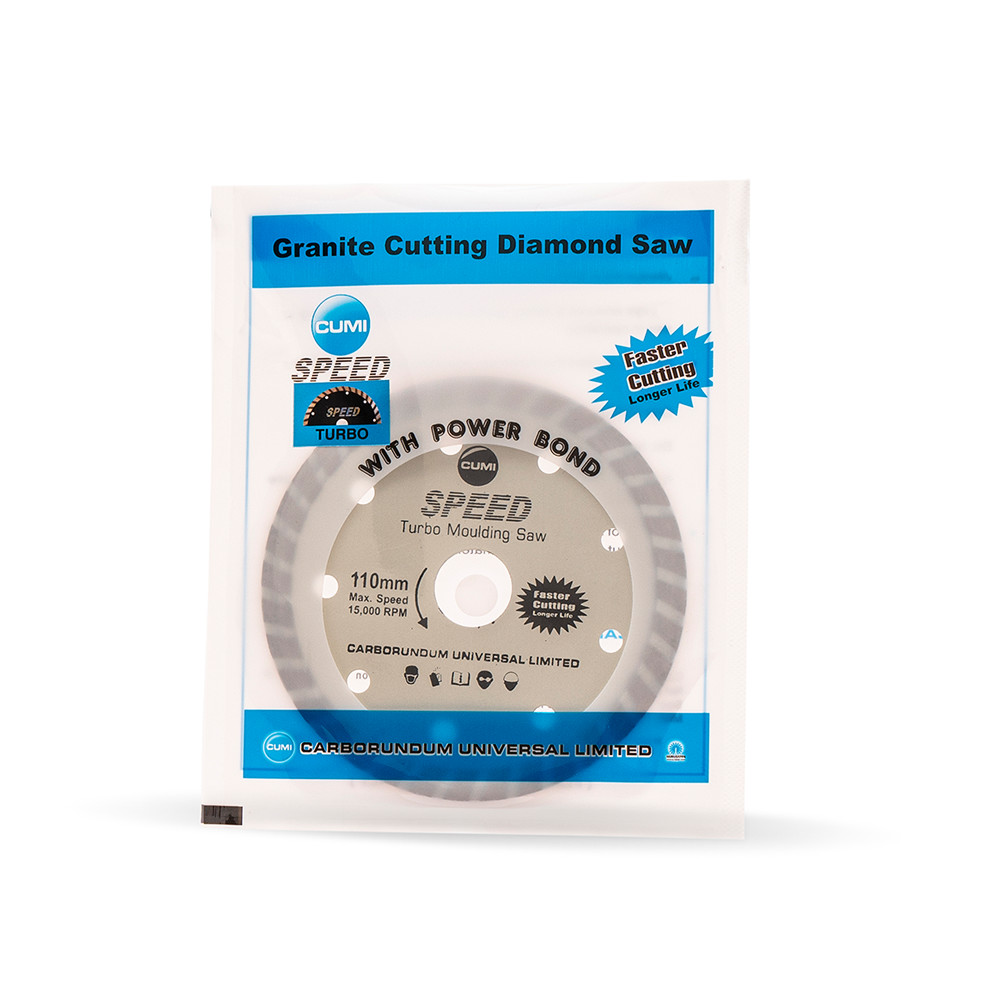

- Diamond Saw

- Fibre Disc

- Flap Disc

- Grinding Wheels

- Hook & Loop Disc

- Non-Woven Abrasives

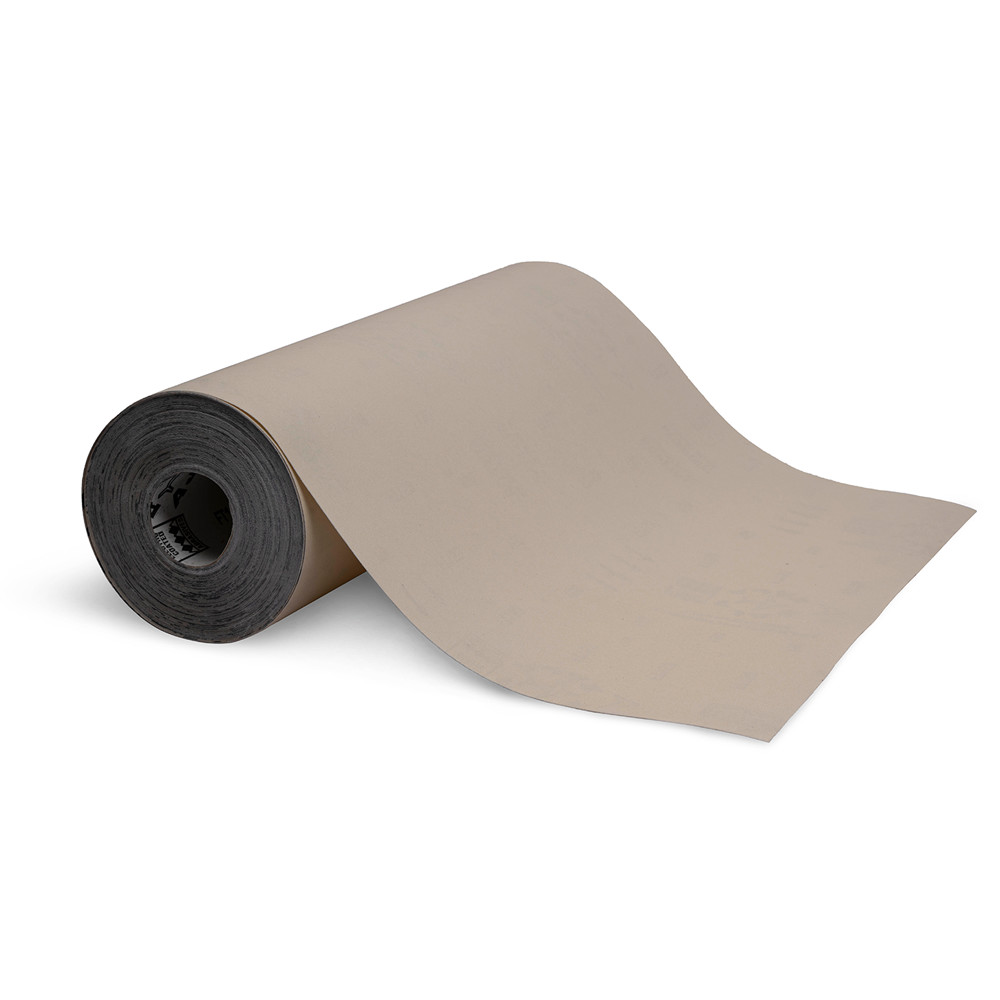

- Rolls

- Sheets

- TCT

- Angle Grinders

- Axles

- Ball

- Billets

- Bright Bar

- Broach

- Buffing

- Cam

- Chopsaws

- Crank

- CRM Rolls

- Curving

- Cutters

- Cutting

- Cylindrical Roller

- Deburring

- Drills

- Engine Valve

- Fastners

- FIE

- Finishing

- Fork Pipe

- Gear

- Heavy Grinding

- High stock removal

- Hobs

- HRM Rolls

- Inserts

- Light Grinding

- Medium Grinding

- Metal Grinding

- Milling

- Needle Roller

- Others

- Piston Ring

- Piston Rod

- Polishing

- Ring Inner race

- Ring Outer Race

- Roughing

- Sanding

- Shafts

- Shaping

- Shaving Cutter

- Sheets

- Spherical Roller

- Spring

- Taper Roller

- Taps

- Turbine Blades

- Vanes

- Wall

- Aluminium

- Bearing Steel

- Copper

- EN Material

- MS Material

- Stainless steel

- steel

- Stone

Showing 31–35 of 35 results

Speed Diamond Segmented Blades are India’s best-selling diamond blades, renowned for their advanced hot press technology and superior performance on granite, marble, Kota, Kadapa, and Tandur. The multipoint sharp edge diamond grains ensure accuracy and minimal vibration, reducing operator fatigue. With a super balanced steel body, these blades guarantee safety and 25% lower machine maintenance.

Read More

Speed Diamond Turbo Blades are engineered with advanced hot press technology and premium large-sized diamonds featuring a unique turbo design.These blades offer exceptional cutting performance, making them ideal for smooth carving and high-speed cutting of hard granite, all while ensuring accuracy with minimal vibration.

Read More

Tezz Plus IDC Disc offers enhanced material removal for wood sanding through its specially processed sharper grains. These discs are designed to last longer and generate less heat, effectively eliminating burn marks, while its unique adhesive prevents grain flaking. Ideal for efficient sanding, delivering quicker results with less effort, making it perfect for to-and-fro motion.

Read More

This product is highly recommended for leather applications. The white aluminium oxide rolls feature a unique flexible bond and smooth paper backing, ensuring excellent flexibility for a scratch-free finish on all leather types. Available in various grits, these rolls are perfect for buffing and snuffing different leathers.

Read MoreFrequently Asked Questions

Abrasives used in construction include:

- Bonded Abrasives – Grinding wheels, cutting discs for heavy-duty grinding and material removal.

- Coated Abrasives – Sandpaper, abrasive belts for surface smoothing and polishing.

- Super Abrasives – Diamond and CBN tools for cutting concrete, tiles, and hard materials.

- Loose Abrasives – Grit blasting materials like aluminum oxide and garnet for cleaning and surface preparation.

The right abrasive depends on:

- Material type – Concrete, metal, wood, or stone.

- Application – Cutting, grinding, polishing, or surface preparation.

- Grit size – Coarse grits (24-60) for heavy removal; finer grits (100-400) for smooth finishes.

- Tool compatibility – Ensure the abrasive fits your grinder, saw, or sander.

- Use moderate pressure to prevent excessive wear.

- Operate at the recommended speed to avoid overheating.

- Store in a dry place to prevent moisture damage.

- Clean abrasives regularly and inspect for wear before use.

- Wear protective gear – goggles, gloves, and a mask.

- Check for cracks or damage before using any abrasive.

- Follow speed limits set by the manufacturer.

- Work in a well-ventilated area to control dust and debris.

- Bonded Abrasives (Grinding wheels, cutting discs) – Used for heavy-duty grinding and cutting.

- Coated Abrasives (Sandpaper, abrasive belts) – Used for smoothing and finishing surfaces.

Contact Us

Ready to enhance your construction projects with our premium abrasive products? Get in touch with our team today to find the perfect solution for your needs. Let’s build success together!Contact Us